In today's fast-paced manufacturing environment, businesses are continuously seeking innovative solutions to enhance operational efficiency and product quality. One such advancement is the use of an Automatic Checkweigher, which has become an essential component in ensuring the accuracy of product weights during packaging processes. According to recent industry reports, up to 60% of manufacturers cite weight accuracy as a critical factor in meeting regulatory standards and consumer expectations. Additionally, integrating automatic checkweighers can reduce waste by up to 10%, significantly improving profitability. By automating the weighing process, companies not only streamline operations but also minimize human error, enhance compliance, and ultimately boost customer satisfaction. As we delve into the unique benefits of utilizing an Automatic Checkweigher, it becomes clear that this technology is not merely a luxury but a necessity for businesses aiming for long-term growth and efficiency.

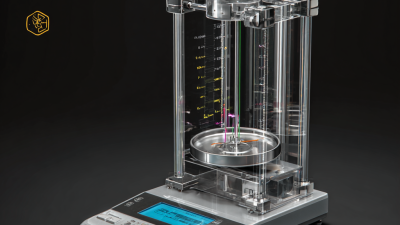

In today's competitive landscape, businesses striving for efficiency and accuracy must consider leveraging advanced technologies. One such innovation is the automatic checkweigher, which plays a crucial role in enhancing product weight accuracy. By utilizing sophisticated sensors and real-time data processing, these machines ensure that each product is weighed precisely before packaging. This not only helps in maintaining consistent quality but also minimizes the risk of costly errors associated with inaccurate product weights.

Moreover, automatic checkweighers are designed to minimize human intervention, effectively reducing the chances of human error during the weighing process. With less manual handling, the likelihood of miscalculations diminishes significantly. This enhanced accuracy not only boosts the reliability of the product but also streamlines the production process, allowing businesses to achieve higher throughput without sacrificing quality. As a result, companies can improve their operational efficiency, enhance customer satisfaction, and maintain compliance with industry standards, ultimately leading to a more successful workflow.

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Enhanced Accuracy | Automatic checkweighers provide precise weight measurements, significantly reducing errors caused by manual weighing. | Increased product consistency and reduced waste. |

| Speed of Operation | These machines can weigh products much faster than human operators, leading to improved throughput. | Higher production rates and faster delivery times. |

| Data Capture | Automatic checkweighers can collect data for analysis, helping identify trends and improve processes. | Informed decision-making and optimized operations. |

| Reduced Labor Costs | Fewer employees are needed for weighing tasks, allowing for shift reallocations. | Lower operational expenses and increased efficiency. |

| Regulatory Compliance | Help ensure accuracy in product weight, aiding compliance with industry regulations. | Reduced risk of fines and recalls. |

| Flexibility | Many checkweighers can be easily adapted to various product types and sizes. | Enhanced adaptability to changing production needs. |

| Error Reduction | Minimizes human error in the weighing process, leading to improved accuracy. | Better quality control, leading to higher customer satisfaction. |

Integrating automatic checkweighers into your production line can significantly enhance efficiency and productivity. These advanced systems not only ensure precise weighing but also streamline the inspection process, enabling businesses to maintain strict quality control. Recent exhibitions have showcased innovations in checkweighing technology, highlighting their versatility in various industries, including pharmaceuticals and food production. By adopting these smart inspection solutions, companies can expect improved operational efficiency while ensuring product safety and compliance with industry standards.

To maximize the benefits of checkweighers, consider the following tips: First, ensure seamless integration with existing production machinery to minimize workflow disruptions. Second, invest in enhanced data management software that can provide insights into your operations, allowing for timely adjustments and informed decision-making. Implementing remote monitoring capabilities can also help in maintaining optimal performance and quick fault identification, thereby reducing downtime. By leveraging these technologies wisely, businesses can achieve a more productive and resilient production line.

Implementing automatic checkweighers in a production line can lead to significant cost savings by minimizing waste. According to a report by the Food and Drug Administration (FDA), improper weight checks can lead to product underfilling and overfilling, which not only affects compliance but also results in substantial financial losses. The automation of this process can reduce material waste by as much as 20%, thereby protecting profit margins and enhancing overall business efficiency.

Industry analysis indicates that companies utilizing automatic checkweighers can see a return on investment (ROI) of up to 300% within the first year of implementation. This is primarily due to improved accuracy in weighing products, leading to a reduction in the costs associated with rework, excess raw materials, and non-compliance penalties. Furthermore, a study from the Packaging Machinery Manufacturers Institute highlighted that businesses experience up to 40% less product giveaway when implementing automated checkweighing systems, translating directly into increased revenue and operational efficiency.

Compliance with regulatory standards is vital for any business that deals with packaged goods. An automatic checkweigher enhances compliance assurance by consistently providing accurate weight measurements. This precision helps businesses avoid fines and legal issues related to mislabeling or inaccurate weights, which can undermine customer trust and impact brand reputation.

When integrating an automatic checkweigher, consider these tips to enhance compliance efficiency: First, ensure the checkweigher is regularly calibrated to maintain accuracy over time. A well-calibrated machine reduces the risk of discrepancies in weight, ensuring that products meet regulations consistently. Second, implement a routine maintenance schedule to prevent mechanical errors that could lead to compliance breaches. This proactive approach not only protects against potential fines but also streamlines operational processes.

Additionally, invest in an automatic checkweigher that can provide real-time data analytics. By analyzing weight data trends, businesses can quickly identify issues in their production line, allowing for immediate corrective actions. This capability not only helps with compliance but also boosts overall business efficiency, making it easier to adhere to regulatory standards while maintaining high-quality product delivery.

In today's fast-paced business environment, real-time monitoring is crucial for making informed decisions that drive efficiency and productivity. Utilizing an automatic checkweigher not only streamlines the weighing process but also provides valuable data insights that can enhance operational performance. By integrating these advanced systems, businesses can track product weights and adherence to specifications instantly, reducing the margin for error and minimizing product wastage.

The ability to analyze real-time data allows companies to respond more swiftly to production anomalies or quality control issues. With comprehensive visibility into weighing operations, managers can identify trends, forecast inventory needs, and optimize supply chain logistics. Importantly, this data-driven approach facilitates proactive decision-making, empowering businesses to adjust strategies and improve overall efficiency.

By leveraging the insights gained from automatic checkweighers, organizations can achieve greater accuracy in their processes, leading to higher customer satisfaction and increased profitability.