In the ever-evolving world of agriculture and food processing, the importance of a reliable Fruit Sorting Machine cannot be overstated. As the demand for high-quality fruits continues to rise, so does the need for efficient sorting technologies that can enhance productivity and ensure market standards are met. This ultimate guide aims to provide in-depth insights into the various factors you should consider when selecting the best Fruit Sorting Machine tailored to your specific needs. From understanding the latest technological advancements to evaluating performance metrics and operational efficiency, we will equip you with the knowledge necessary to make an informed decision. Whether you're a small-scale farmer or a large-scale distributor, mastering the selection process of a Fruit Sorting Machine is crucial for staying competitive in today's fast-paced market, and we are here to help you navigate this essential investment.

When selecting a fruit sorting machine, several key factors must be considered to ensure optimal efficiency and effectiveness. According to a report by MarketsandMarkets, the global fruit sorting machine market is anticipated to grow at a CAGR of 5.6% from 2021 to 2026, emphasizing the increasing importance of advanced sorting technologies in the agricultural sector. One crucial aspect to evaluate is the machine’s sorting accuracy, as even a 1% increase in accuracy can significantly impact yield and profitability. Advanced machines use sophisticated algorithms and optical sensors to detect ripeness, size, and defects, which can drastically reduce manual sorting time.

When selecting a fruit sorting machine, several key factors must be considered to ensure optimal efficiency and effectiveness. According to a report by MarketsandMarkets, the global fruit sorting machine market is anticipated to grow at a CAGR of 5.6% from 2021 to 2026, emphasizing the increasing importance of advanced sorting technologies in the agricultural sector. One crucial aspect to evaluate is the machine’s sorting accuracy, as even a 1% increase in accuracy can significantly impact yield and profitability. Advanced machines use sophisticated algorithms and optical sensors to detect ripeness, size, and defects, which can drastically reduce manual sorting time.

Another important consideration is the machine’s capacity and speed. As highlighted in a research study published by the Food Processing Technology Journal, modern fruit sorting machines can process up to 24 tons of fruit per hour, making them indispensable for larger farms and packinghouses. Additionally, the versatility of the sorting machine is vital; many models now accommodate various fruit types, from apples to berries, allowing for greater flexibility in operations. Investing in a machine that balances speed, accuracy, and adaptability ensures that businesses can enhance their operational workflows while meeting market demands.

When choosing the best fruit sorting machine, understanding the advantages of various sorting technologies is crucial for optimizing operational efficiency and product quality. According to a report by MarketsandMarkets, the global fruit sorting machine market is expected to grow significantly, reaching $1.37 billion by 2025, driven by the increasing demand for high-quality processed fruits. Different technologies cater to diverse sorting needs, including optical sorting, mechanical sorting, and x-ray technology.

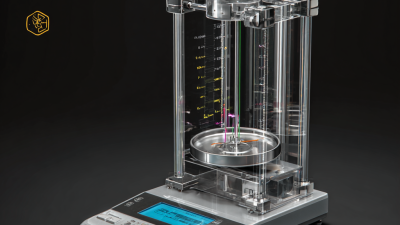

Optical sorting machines utilize advanced camera systems and algorithms to analyze and sort fruits based on size, color, and defects. This technology boasts accuracy rates exceeding 99%, which can enhance productivity by minimizing manual sorting and reducing waste. Industry standards indicate that for every 1% increase in sorting accuracy, fruit packers can improve their profit margins by an average of 2-3%. Meanwhile, mechanical sorting systems provide a cost-effective solution for larger fruit varieties, allowing bulk sorting while maintaining a faster operational pace. Lastly, x-ray sorting technology, though more specialized, offers the unique advantage of detecting internal defects, ensuring that only the highest quality fruits reach consumers.

By identifying the strengths of each sorting technology, businesses can make informed decisions that align with their product specifications and market demands, ultimately leading to improved customer satisfaction and profitability.

When it comes to the fruit packing and processing industry, efficiency and profitability are paramount. Fruit sorting machines play a crucial role in enhancing these factors by automating the sorting process, which traditionally has been labor-intensive and time-consuming. By employing advanced technologies, such as optical sorting systems and artificial intelligence, these machines can quickly and accurately classify fruits based on size, color, and quality. This not only speeds up the workflow but also minimizes human error, leading to higher quality products and increased customer satisfaction.

Moreover, the investment in a reliable fruit sorting machine can significantly boost a company's bottom line. With the ability to process large volumes of fruit rapidly, businesses can expand their operations and meet higher demand without sacrificing quality. The precision of sorting machines also reduces waste, ensuring that only the best fruits reach consumers while less desirable ones are efficiently handled for other purposes. Thus, integrating fruit sorting machines into production lines not only streamlines operations but also maximizes profitability through improved product quality and reduced operational costs.

When selecting a fruit sorting machine, one of the most critical factors to consider is its sorting capacity. Different models offer varying capacities, which can significantly impact your operational efficiency and profitability. According to a recent report by MarketsandMarkets, the global market for fruit sorting machines is expected to grow at a CAGR of 6.2% from 2021 to 2026, largely driven by advancements in sorting technology and the increasing demand for high-quality produce. For instance, a machine capable of sorting 5 tons of fruit per hour can drastically reduce labor costs and improve throughput compared to smaller models.

In addition to capacity, the speed at which a sorting machine operates is equally important. Sorting speeds can range from 1 to 10 tons per hour, depending on the sophistication of the technology used. Many modern machines are equipped with advanced imaging systems that can detect size, color, and defects at remarkable speeds, ensuring only the best fruit reaches consumers. A study published by the Journal of Food Engineering highlights that utilizing high-capacity sorting machines leads to a 20% increase in productivity, emphasizing the need for producers to evaluate not just their current needs but future growth potential when making their selection.

This chart illustrates the number of fruit sorting machines available in different capacity ranges. Understanding these capacities can help you choose the best sorting machine that fits your operational needs.

Maintaining your fruit sorting machine is crucial to ensure its longevity and optimal performance. Regularly inspect and clean the conveyor belts and sorting mechanisms to prevent build-up of dirt and residues. A clean machine operates more efficiently and reduces the risk of product contamination. Additionally, consider using soft brushes or cloths to avoid damaging any sensitive components.

One essential tip is to perform routine lubrication of moving parts. This reduces friction and wear, prolonging the life of your machine. It's advisable to follow the manufacturer’s guidelines on lubrication frequency and types of lubricants to use. Be sure to regularly check for any signs of wear on belts and rollers, replacing them immediately if you notice significant degradation to avoid larger issues down the line.

Lastly, keep an eye on the electrical systems and sensors of your sorting machine. Dust and moisture can cause malfunctions, so maintaining a clean environment around the machine is necessary. Conduct periodic checks to ensure all components are functioning correctly, and be proactive in addressing any minor issues before they become larger, costly repairs.