In today's highly competitive manufacturing landscape, the efficient and precise management of product weights is pivotal to ensuring product quality and compliance with industry regulations. The global checkweighing machine market is projected to grow significantly, with a valuation expected to reach USD 1.12 billion by 2025, driven by increasing demand for automation and the need for enhanced quality control processes.

As businesses strive to optimize their operations, investing in top-quality checkweighing machines not only improves accuracy but also elevates overall productivity and customer satisfaction. By sourcing superior equipment from reputable suppliers, companies can leverage the technological advancements in checkweighing machines, ultimately increasing their operational efficiency and solidifying their standing in the global market.

In the context of "中国制造,以品质赢得世界尊重," it is essential for manufacturers to prioritize quality in their equipment choices to earn respect and recognition on the world stage.

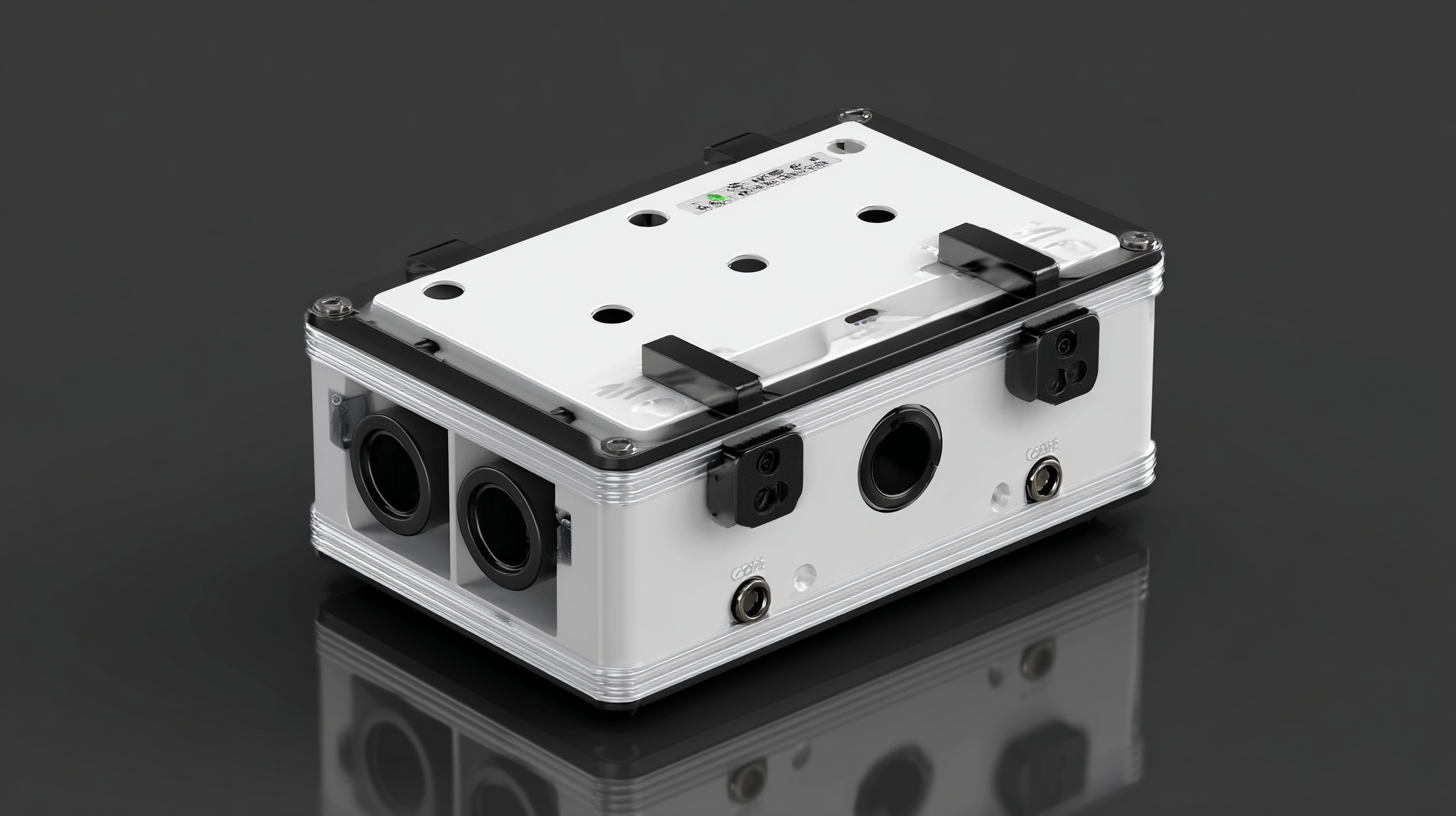

When investing in a checkweighing machine, understanding its key features is crucial for ensuring optimal performance. High-quality machines often come equipped with advanced technology that can accurately measure weight with minimal error. Look for machines that offer a high level of precision, as even small discrepancies can affect product quality and compliance with regulations. Additionally, reliable checkweighers should have a robust construction that can withstand the demands of a fast-paced production environment.

Tips: When assessing checkweighing machines, pay attention to the speed of measurement. A machine that combines speed with accuracy will enhance your operational efficiency. Moreover, consider the user interface; machines with intuitive controls can reduce training time for operators and minimize the chances of human error. Finally, maintenance features can also play a significant role in long-term machine performance; machines that are easy to clean and maintain can save time and resources in the long run.

Another important aspect to consider is connectivity features. A modern checkweighing machine should easily integrate with your existing systems, allowing for seamless data transfer and real-time monitoring. This capability not only enhances productivity but also provides valuable insights into your operations, enabling you to make informed decisions to improve efficiency.

In the ever-evolving landscape of the food and beverage industry, the demand for precise checkweighing solutions has become increasingly vital. As food safety regulations tighten and consumers become more discerning about product quality, manufacturers are realizing the importance of accuracy in product weight. This shift is not merely a regulatory necessity but a strategic move to enhance operational efficiency and maintain competitiveness in a crowded market.

As businesses look to improve their supply chain logistics and meet evolving consumer expectations, investments in high-quality checkweighing machines are on the rise. Analyzing the trends in plastic packaging materials, such as polypropylene (PP) and polyethylene (PE), reveals that the demand for robust and reliable packaging solutions is also echoed in the checkweighing equipment market. With various applications for products ranging from cups and trays to unique lid designs, a focus on accuracy in the packaging process contributes significantly to quality assurance and operational productivity, ensuring that businesses can thrive in the modern marketplace.

When selecting a checkweighing machine, evaluating supplier credentials is crucial to ensure that you partner with a reliable manufacturer. First, look for suppliers with a solid track record in the industry, backed by certifications and proven performance metrics. These credentials not only reflect their commitment to quality but also their ability to meet stringent standards essential for your operational needs.

Incorporating a structured evaluation process can further enhance your decision-making. Recent methodologies emphasize employing multi-criteria decision-making (MCDM) models that assess suppliers based on economic, environmental, and social factors. By integrating these criteria, businesses can build a resilient supply base, capable of adapting to challenges such as those presented during the COVID-19 pandemic. Moreover, leveraging technology like data-driven support vector regression can streamline the evaluation process, allowing for more informed supplier selections that align with your sustainability goals.

In today’s competitive market,

advanced checkweighing machines

are becoming essential tools for improving operational efficiency and minimizing waste in production environments.

These machines not only ensure precise weight measurements but also integrate seamlessly with various inspection technologies,

such as X-ray and vision systems.

By adopting such technologies, businesses can achieve better quality control, ensuring that products meet regulatory standards

while reducing the risk of errors that could lead to excess waste.

Moreover, the growing

Automatic Checkweigher Market

is a testament to the increasing reliance on automation across industries.

Forecasts suggest significant growth, driven by the demand for efficiency and accuracy in packaging and production lines.

Implementing smart checkweighing solutions enables companies to utilize

Statistical Quality Control (SQC),

which enhances production line performance through immediate identification of deviations in weight.

This transition to automation not only fosters an environment of continuous improvement but also leads to substantial cost savings,

as manufacturers can optimize their operations and reduce the potential for overfilling or underfilling products.

When investing in a checkweighing machine, it's crucial to ensure that your equipment complies with all relevant regulatory requirements. Compliance standards can vary significantly between industries and regions, so understanding the specific regulations that apply to your business will help you avoid costly fines and operational disruptions. For example, food and beverage industries often adhere to strict guidelines to ensure product safety and quality, requiring accurate weight measurements to prevent overfilling and underfilling.

**Tip:** Regularly review the compliance standards for your industry. Stay updated on any changes in regulations, as these can impact your operations and the machines you choose. Consider aligning with suppliers who prioritize quality control and compliance in their manufacturing processes.

Choosing a supplier that understands and specializes in compliance is paramount. They should provide detailed information about how their checkweighing machines meet industry standards, along with certifications and technical documentation. This not only ensures compliance but also enhances the reliability and performance of your equipment.

**Tip:** Ask suppliers for references or case studies that demonstrate their success in helping other businesses achieve compliance. This can provide peace of mind that you're investing in a product that meets stringent industry requirements.

| Supplier Location | Machine Type | Max Capacity (kg) | Compliance Standards | Warranty Period (years) |

|---|---|---|---|---|

| USA | Belt Checkweigher | 150 | ISO 9001, CE | 2 |

| Germany | Dynamic Checkweigher | 80 | OIML, HACCP | 3 |

| Japan | In-line Checkweigher | 200 | JIS, ISO 14001 | 5 |

| China | Portable Checkweigher | 50 | CCC, CE | 1 |

| UK | Heavy-duty Checkweigher | 300 | MID, ISO 9001 | 4 |