In the fast-evolving world of agriculture and food processing, the importance of adopting advanced technologies is more pronounced than ever. Among these innovations, the Mandarin Sorting Machine stands out as an essential tool for optimizing the sorting and grading of mandarin oranges. As the demand for high-quality fruits continues to rise, it becomes crucial for producers to utilize machines that not only enhance efficiency but also ensure superior product quality.

The year 2025 promises to showcase several cutting-edge Mandarin Sorting Machines that come packed with features designed to streamline operations and increase productivity. These machines are equipped with advanced imaging technology, allowing for precise sorting based on size, color, and quality. This not only results in reduced labor costs but also minimizes human error, providing a reliable solution for fruit sorting.

As we delve into the top five Mandarin Sorting Machines of 2025, we will explore the unique features and benefits each machine offers. From enhanced automation to improved output capacity, these innovations are set to redefine the standards of fruit sorting in the industry, empowering growers to meet consumer expectations and maintain competitiveness in the market.

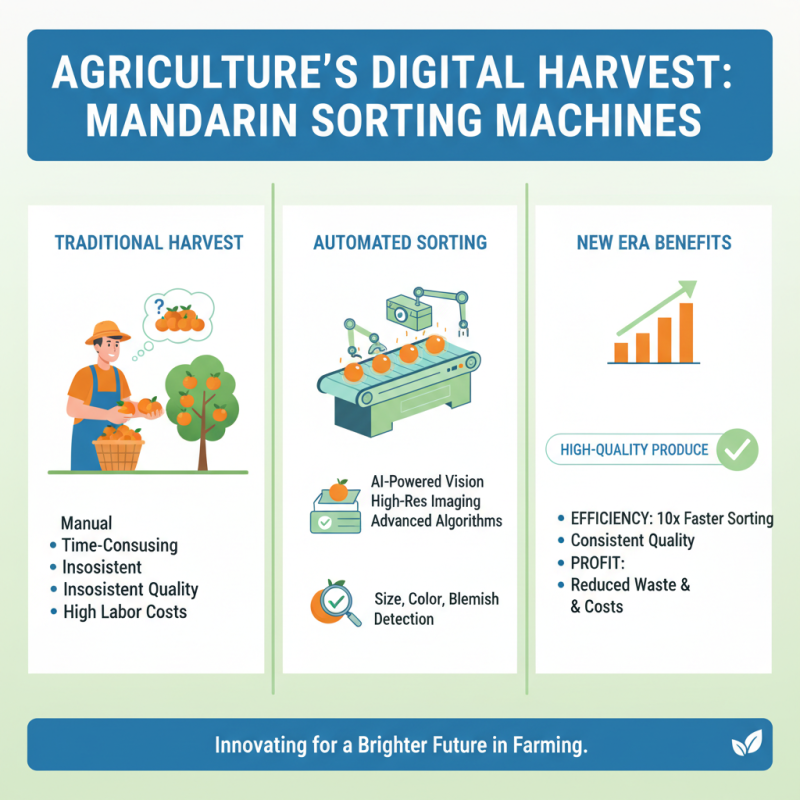

The rise of mandarin sorting machines in agriculture marks a significant trend toward greater efficiency and precision in fruit harvesting. As the demand for high-quality produce increases, farmers are increasingly turning to advanced technology to streamline their operations. These sorting machines utilize innovative algorithms and high-resolution imaging to evaluate the size, color, and blemishes of mandarins, enabling growers to select only the best fruits for sale. This automated process not only saves time but also reduces labor costs and minimizes human error, ensuring a consistent product quality.

Moreover, the incorporation of mandarin sorting machines into agricultural practices is transforming the way producers operate. With the help of such machines, farms can now increase their productivity while maintaining stringent quality control standards. This is particularly important in the competitive market where consumers are more discerning about the produce they purchase. As a result, these machines not only contribute to the overall quality of the harvest but also help farmers enhance their marketability, ultimately supporting a more sustainable agricultural ecosystem.

When considering the leading mandarin sorting machines of 2025, key features play a significant role in enhancing efficiency and ensuring quality.

Firstly, advanced imaging technology is a critical component. These machines employ high-resolution cameras and artificial intelligence algorithms to analyze the size, color, and surface quality of the mandarins.

This not only allows for precise sorting based on market standards but also helps in identifying defects that may not be visible to the naked eye, leading to better product quality and reduced waste.

Additionally, the automation capabilities of these sorting machines contribute to increased overall productivity. With features such as real-time monitoring and adjustable sorting parameters,

operators can easily accommodate different varieties of mandarins without extensive manual intervention.

The integration of user-friendly interfaces also streamlines operations, enabling staff to manage sorting processes efficiently.

Furthermore, many machines are designed to be energy-efficient, which not only lowers operational costs but also supports sustainable practices in agricultural processing.

These features collectively ensure that the mandarin sorting process in 2025 is more accurate, efficient, and aligned with modern agricultural demands.

The citrus processing industry is witnessing a transformative surge with the incorporation of advanced sorting technology. These state-of-the-art Mandarin sorting machines efficiently enhance quality control and operational productivity. According to a recent industry report, the adoption of automated sorting technologies can increase sorting accuracy by up to 95%, significantly reducing the risk of human error and ensuring that only the best fruits reach consumers.

Employing modern sorting technologies not only streamlines operations but also leads to greater economic savings in the long run. By minimizing waste and optimizing resource usage, processing facilities can significantly reduce costs. A survey conducted by the Citrus Industry Association revealed that facilities utilizing advanced sorting technology experienced a 30% decrease in overhead expenses related to labor and waste management. This efficiency allows processors to focus on other critical areas such as marketing and distribution.

Tips for maximizing the benefits of sorting technology include regularly updating sorting software to leverage improvements and conducting routine maintenance of machinery for optimal performance. Additionally, training staff on the latest sorting technologies can further enhance productivity and ensure that everyone is aligned with new operational standards. Implementing these practices can help businesses stay competitive in a rapidly evolving market.

In recent years, the demand for efficient and accurate mandarin sorting machines has surged, driven by the increasing need for quality assurance in the citrus industry. A comparative analysis of the top five mandarin sorting machines of 2025 reveals various innovative features that cater to modern agricultural needs. According to a report by the Agricultural Equipment Manufacturers Association, advanced optical sorting technology has enhanced the precision of grading mandarins, achieving up to 98% sorting accuracy. This not only reduces labor costs but also ensures that consumers receive high-quality fruit.

Furthermore, the integration of artificial intelligence in these machines allows for real-time data analysis and decision-making, resulting in increased operational efficiency. The latest models come equipped with smart sensors that can detect imperfections such as bruising or discoloration, significantly minimizing the incidence of defective products reaching the market. Reports indicate that incorporating AI-driven processes can reduce sorting time by as much as 50%, which is crucial during peak harvesting seasons when time is of the essence. This technological advancement is paving the way for more sustainable practices in mandarin production, as fewer resources are wasted on subpar fruits.

| Machine Model | Sorting Capacity (tons/hour) | Technology Used | Weight (kg) | Key Features |

|---|---|---|---|---|

| Model A | 5 | Laser Sorting | 1200 | High Accuracy, Compact Design |

| Model B | 8 | Optical Sorting | 1500 | Speed Adjustment, Dual Camera System |

| Model C | 6 | Infrared Technology | 1300 | User-Friendly Interface, Low Energy Consumption |

| Model D | 7 | Weight and Size Sorting | 1600 | Robust Construction, Modular Design |

| Model E | 9 | Smart AI Sorting | 1400 | Automated Reporting, Remote Monitoring |

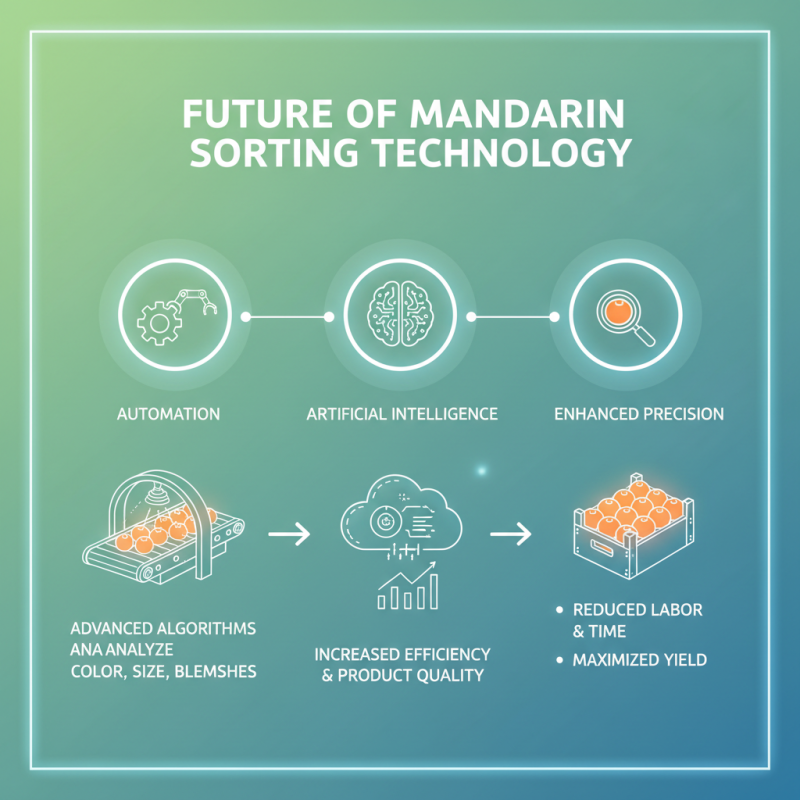

As the agricultural industry evolves, so does the technology utilized for sorting fruits, particularly mandarins. The future trends in mandarin sorting technology revolve around automation, artificial intelligence, and enhanced precision. Advanced algorithms will enable sorting machines to analyze fruit characteristics such as color, size, and blemishes with remarkable accuracy. This technological leap will allow producers to significantly increase efficiency, reducing both labor costs and sorting time while maximizing product quality.

Another critical trend is the integration of sustainability in mandarin sorting processes. New machines are being designed to minimize waste and energy consumption. Techniques like optical sorting and gentle handling will not only improve the quality of the mandarins but also reduce damage during processing. Additionally, innovations such as real-time data analytics will allow producers to track sorting performance and yield, enabling better decision-making. By adopting these cutting-edge advancements, the mandarin industry can look forward to enhanced productivity and sustainability, setting the stage for a more efficient future.