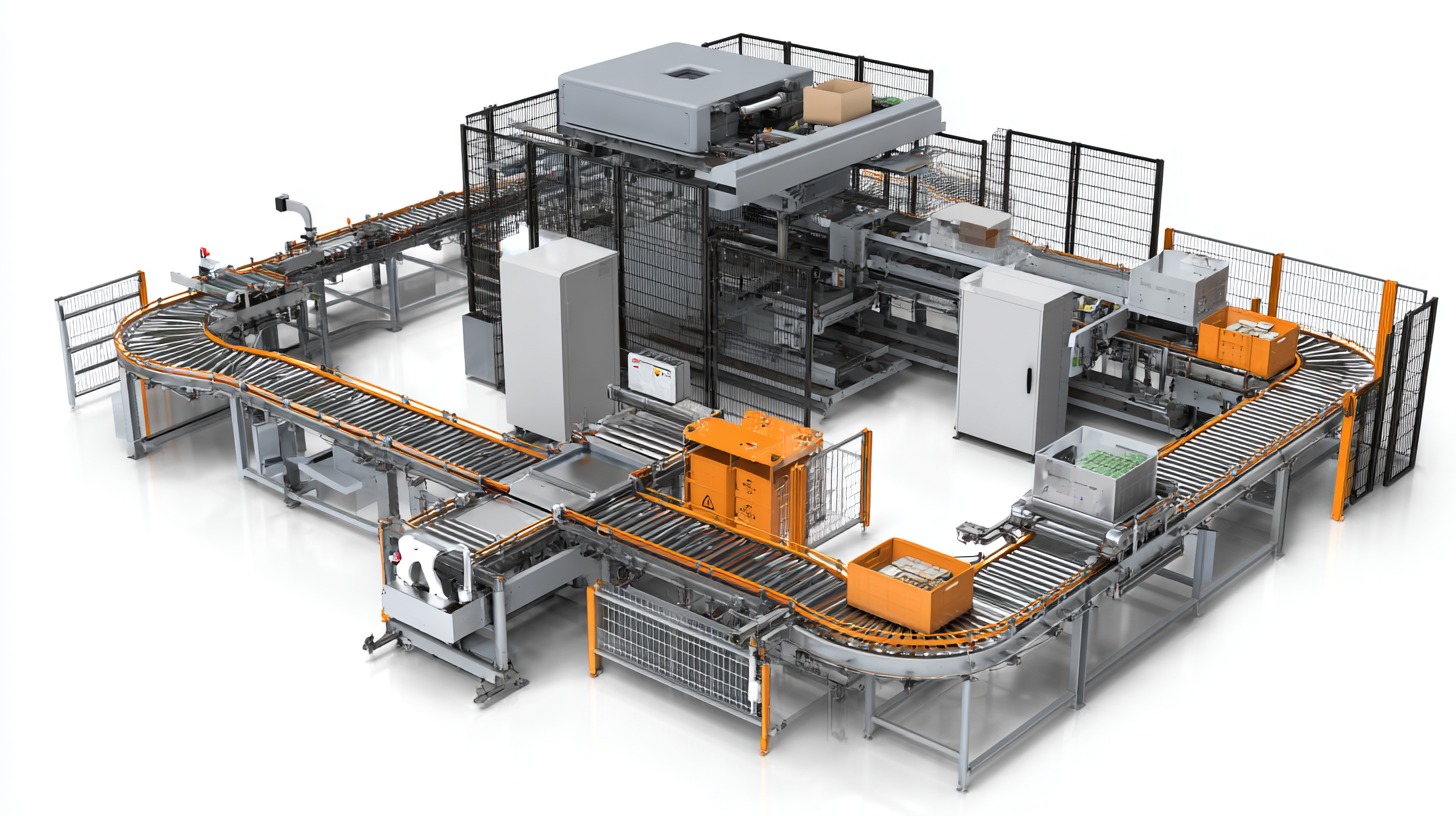

In today's fast-paced manufacturing environment, optimizing production lines for maximum efficiency is paramount for staying competitive. Among the myriad of technologies available, the

Rotary Collecting Table Machine has emerged as a game changer, aimed at streamlining operations and reducing downtime. According to a recent industry report by Grand View Research, the global market for automated machinery is expected to reach $300 billion by 2025, driven by the increasing demand for efficiency and precision in manufacturing processes.

The Rotary Collecting Table Machine not only enhances product flow but also minimizes manual handling, contributing to a significant reduction in labor costs and potential bottlenecks. By integrating these machines into production lines, manufacturers can improve throughput by up to 30%, ultimately leading to substantial cost savings and heightened operational performance. Embracing this technology is not just a trend; it's a strategic move towards achieving excellence in production efficiency.

The Rotary Collecting Table Machine not only enhances product flow but also minimizes manual handling, contributing to a significant reduction in labor costs and potential bottlenecks. By integrating these machines into production lines, manufacturers can improve throughput by up to 30%, ultimately leading to substantial cost savings and heightened operational performance. Embracing this technology is not just a trend; it's a strategic move towards achieving excellence in production efficiency.

In the realm of modern manufacturing, the role of rotary collecting tables cannot be overstated when it comes to enhancing production line efficiency. These machines are crucial for streamlining the flow of materials, allowing for seamless transitions between various stages of the production process. By integrating a rotary collecting table into your production line, you can minimize bottlenecks and maximize throughput, thus ensuring that operations run smoothly and without interruption.

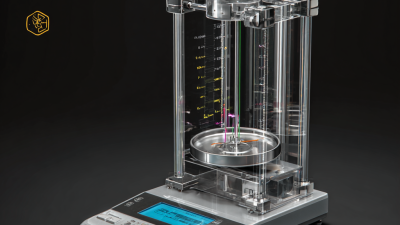

The design of rotary collecting tables allows for easy handling of products at various stages of production. They typically feature a circular layout that allows operators to access different areas of the collecting table quickly and efficiently. This accessibility reduces downtime and enables workers to focus on quality control and other critical tasks. Moreover, with their capability to accommodate multiple outlet connection points, rotary collecting tables can be tailored to fit specific production needs, making them a versatile asset in boosting overall efficiency. By implementing these machines, manufacturers can optimize their operations and ultimately achieve higher productivity levels.

The integration of rotary collecting table machines in production lines can significantly enhance efficiency, but understanding their impact is crucial. To measure this impact, focus on key metrics such as output rates, cycle times, and downtime. By analyzing these metrics, manufacturers can identify bottlenecks and optimize their processes, ensuring that every part of the production line works cohesively and effectively.

Tip 1: Regularly monitor your output rates before and after implementing rotary collecting tables. This data will help you gauge their effectiveness in reducing cycle times. By establishing a baseline measurement, you can make informed adjustments to further enhance efficiency.

Tip 2: Track downtime meticulously. Analyze the reasons behind any delays and determine if they are related to the setup of the rotary collecting tables or other machinery. Understanding these patterns allows for timely interventions that can help minimize disruptions.

Tip 3: Consider employee training on the new systems in place. Engaging staff in the operation and troubleshooting of rotary collecting table machines enhances their productivity and reduces error rates, ultimately contributing to improved overall output.

Integrating rotary collecting tables into existing production systems can significantly enhance efficiency and streamline operations. These machines serve as pivotal points in a production line, facilitating the smooth transition of products between various stages of manufacturing. To successfully incorporate rotary collecting tables, it's essential to conduct a thorough analysis of the current workflow. Identifying bottlenecks and understanding the specific needs of your production line will allow you to position the tables optimally, ensuring minimal disruption while reaping maximum benefits.

Another best practice is to focus on compatibility and scalability. When selecting rotary collecting tables, ensure they align with your existing equipment and can adapt to any future expansions or changes in production demands. Training staff on the new system is equally important, as skilled operators can significantly reduce downtime and enhance productivity. Furthermore, regular maintenance and updates to both the collecting tables and the surrounding machinery will foster a more reliable and efficient production environment. Embracing these strategies will not only optimize your production line but also position your operation for sustainable growth.

Rotary collecting tables have proven to be a game-changer in enhancing production line efficiency across various industries. A recent report by the International Journal of Production Research indicates that manufacturers implementing rotary collecting table machines have observed up to a 30% increase in throughput and a significant reduction in bottleneck occurrences. For instance, in the automotive sector, the use of rotary tables has streamlined parts assembly processes, allowing for a continuous flow of components while minimizing manual handling. This automation not only increases speed but also boosts worker safety by reducing repetitive strain injuries.

In the food and beverage industry, case studies reveal that companies adopting rotary collecting tables have achieved remarkable results, with some reporting an increase in packaging efficiency by as much as 25%. The Association for Packaging and Processing Technologies highlights that incorporating these machines can lead to faster line changeovers, thus allowing manufacturers to adapt quickly to changing consumer demands. Furthermore, rotary collecting tables facilitate better space utilization on the production floor, making it easier to meet both large-scale production goals and regulatory standards for quality control.

In recent years, the manufacturing industry has seen remarkable advancements in rotary collecting table technology, significantly enhancing productivity on production lines. According to a report by the International Journal of Production Research, incorporating automated rotary collecting tables can reduce material handling time by up to 25%, allowing businesses to maximize output and reduce operational costs. These innovations, ranging from improved automation to smarter integration with existing systems, highlight the trend towards more adaptive and efficient manufacturing environments.

Tips: To fully leverage the benefits of rotary collecting tables, consider integrating sensors and IoT technology to monitor real-time performance. This allows for timely adjustments and predictive maintenance, ultimately leading to reduced downtime and increased production efficiency.

Moreover, the ability to customize rotary tables according to specific production needs is becoming a crucial trend. A study by the Manufacturing Institute noted that customization can lead to a 30% improvement in workflow efficiency. Companies that invest in tailor-made solutions for rotary systems can expect a more streamlined production process, directly impacting their bottom line.

Tips: Regular training for staff on new technologies and systems can significantly enhance their effectiveness in utilizing these innovations, ensuring that your production line remains competitive and efficient.