In today's highly competitive manufacturing landscape, optimizing production efficiency is paramount for success. Recent industry reports indicate that manufacturers incorporating advanced technologies can enhance their operational productivity by up to 30%. Among these technologies, the Roller Checkweigher stands out as a vital tool for ensuring accuracy and compliance in product weight measurements.

In today's highly competitive manufacturing landscape, optimizing production efficiency is paramount for success. Recent industry reports indicate that manufacturers incorporating advanced technologies can enhance their operational productivity by up to 30%. Among these technologies, the Roller Checkweigher stands out as a vital tool for ensuring accuracy and compliance in product weight measurements.

By automating the weighing process, Roller Checkweighers not only minimize human error but also accelerate throughput rates, thus streamlining the production line. Additionally, organizations that implement this technology report a significant reduction in product wastage and increased overall profitability. As the demand for quality control intensifies, leveraging Roller Checkweigher technology becomes essential for manufacturers aiming to maintain their competitive edge while adhering to stringent regulatory standards.

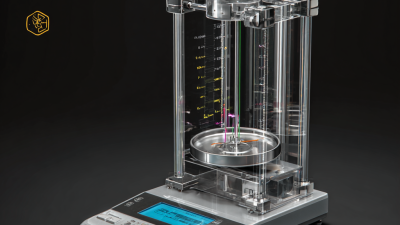

Roller checkweigher technology has revolutionized the way production lines manage weight verification and quality control. This advanced system operates by using rollers to transport products while continuously measuring their weight. The significant benefits of roller checkweighers include enhanced accuracy, increased speed, and the ability to identify discrepancies in real time. This not only reduces waste but also ensures that all products meet regulatory and quality standards, thus improving overall operational efficiency.

Tips for Implementation: When integrating roller checkweigher technology into your production line, it's essential to calibrate the system regularly. This ensures that it remains sensitive to weight variations and maintains accuracy over time. Additionally, consider training your staff on how to interpret checkweigher data, as this knowledge can help in making informed decisions that positively impact production efficiency.

Another important tip is to choose a roller checkweigher that fits seamlessly with your existing production equipment. Compatibility can minimize downtime and ensure a smoother transition. Regular maintenance of the equipment is also crucial to avoid unexpected malfunctions that could disrupt the production flow.

Roller checkweighers are integral to modern production lines, offering crucial features that enhance operational efficiency and accuracy. One of the standout characteristics is their ability to perform real-time weighing without interrupting the production flow. This allows manufacturers to immediately identify discrepancies in weight, ensuring that products meet specified standards before they proceed to the next stages. According to industry reports, implementing advanced checkweighing technology can improve overall efficiency by up to 20%, significantly reducing waste and costs associated with product discrepancies.

Roller checkweighers are integral to modern production lines, offering crucial features that enhance operational efficiency and accuracy. One of the standout characteristics is their ability to perform real-time weighing without interrupting the production flow. This allows manufacturers to immediately identify discrepancies in weight, ensuring that products meet specified standards before they proceed to the next stages. According to industry reports, implementing advanced checkweighing technology can improve overall efficiency by up to 20%, significantly reducing waste and costs associated with product discrepancies.

Another key feature of roller checkweighers is their adaptability to various production environments. With recent advancements in automation technologies, such as those noted in the new glass production line projects, these devices can be seamlessly integrated into manufacturing processes. This integration not only streamlines production but also enhances data collection, enabling manufacturers to make informed decisions based on real-time analytics. With manufacturers increasingly shifting towards smart production lines, utilizing roller checkweighers can be a strategic move to ensure quality and efficiency in the face of evolving market demands.

Integrating roller checkweighers into your existing workflow can significantly enhance production efficiency and product quality. Unlike traditional checkweighers, roller checkweighers use a series of rollers to support product movement, minimizing contact and reducing wear on both the equipment and products. This design allows for smoother handling of items, particularly those that are fragile or sensitive to pressure. By introducing this technology, manufacturers can easily streamline the weighing process without disrupting the current production line configuration.

To successfully implement roller checkweighers, it is essential to conduct a thorough analysis of your existing workflow. Identify the key points where weighing is crucial, ensuring that the roller checkweigher is strategically placed to capture products at optimal intervals. Additionally, integrating these systems with your production management software can provide real-time data and alerts, facilitating immediate adjustments. Training staff on the proper use and maintenance of roller checkweighers will further enhance operational efficiency, reducing downtime and ensuring consistent product quality throughout the production process.

| Dimension | Value | Notes |

|---|---|---|

| Throughput Rate | 1500 units/hour | Maximum production capability |

| Accuracy | ±0.5 grams | Precision of weight measurement |

| Integration Time | 2 weeks | Setup and calibration duration |

| Maintenance Interval | 6 months | Scheduled for optimal performance |

| Cost Savings | 20% reduction | Annual operating costs |

When implementing roller checkweighers in a production line, common challenges can arise that may hinder efficiency and accuracy. One prevalent issue is the inconsistent speed of the conveyor belt, which can lead to varying weight readings as products move through the checkweigher. To mitigate this challenge, companies can invest in advanced speed stabilization technology that synchronizes conveyor belt speed with the checkweighing mechanism, ensuring a consistent measurement regardless of operational fluctuations.

Another challenge is the calibration of the roller checkweighers. Inaccurate calibration can result in false rejections or approvals of products, affecting overall productivity and quality control. Regular maintenance and routine calibration checks are vital in addressing this issue. Implementing an automated calibration system can streamline this process, allowing for quick adjustments and ensuring that the checkweighers deliver precise readings over time. By proactively identifying and resolving these challenges, manufacturers can maximize the effectiveness of roller checkweigher technology and enhance their production line performance.

Maintaining efficiency in roller checkweighers is crucial for optimizing production lines. According to a report by the International Society of Automation, manufacturing efficiency can improve by 20-30% with proper weight verification systems in place. One of the best practices for ensuring roller checkweigher performance is regular calibration. This enhances accuracy, ensuring that all products meet regulatory standards. Regular calibration checks should be scheduled bi-weekly, especially in high-volume settings, to prevent costly errors and product rejections.

Another essential practice involves routine cleaning and maintenance. A study by the Food and Drug Administration indicated that contaminants can lead to weight discrepancies, affecting overall product quality. Implementing a daily cleaning protocol can mitigate these risks and prolong the lifespan of your checkweigher. Additionally, training employees on the operation and maintenance of the equipment is vital, as a knowledgeable workforce can troubleshoot minor issues before they escalate, leading to downtime. By integrating these best practices, manufacturers can significantly increase their roller checkweigher efficiency and enhance overall production line performance.

This bar chart illustrates the efficiency improvements observed in various production metrics after implementing roller checkweigher technology across the production line in general terms. The metrics include Accuracy, Speed, and Cost Reduction, reflecting the overall impact of the technology on manufacturing processes.