In the ever-evolving landscape of manufacturing, precision and efficiency are paramount to maintaining a competitive edge.

Dynamic Checkweighers have emerged as an essential tool for optimizing production lines, offering unparalleled accuracy that can boost operational precision by an impressive 99.5%.

This article delves into the various aspects of integrating Dynamic Checkweighers into your production processes, highlighting their role in eliminating weight discrepancies, reducing waste, and ensuring compliance with industry standards.

By leveraging advanced technology, manufacturers can not only enhance the quality of their products but also streamline their operations, leading to significant cost savings and increased customer satisfaction.

Join us as we explore the transformative impact of Dynamic Checkweighers on modern production lines and how they can help your business achieve new heights of success.

Dynamic Checkweighers have emerged as an essential tool for optimizing production lines, offering unparalleled accuracy that can boost operational precision by an impressive 99.5%.

This article delves into the various aspects of integrating Dynamic Checkweighers into your production processes, highlighting their role in eliminating weight discrepancies, reducing waste, and ensuring compliance with industry standards.

By leveraging advanced technology, manufacturers can not only enhance the quality of their products but also streamline their operations, leading to significant cost savings and increased customer satisfaction.

Join us as we explore the transformative impact of Dynamic Checkweighers on modern production lines and how they can help your business achieve new heights of success.

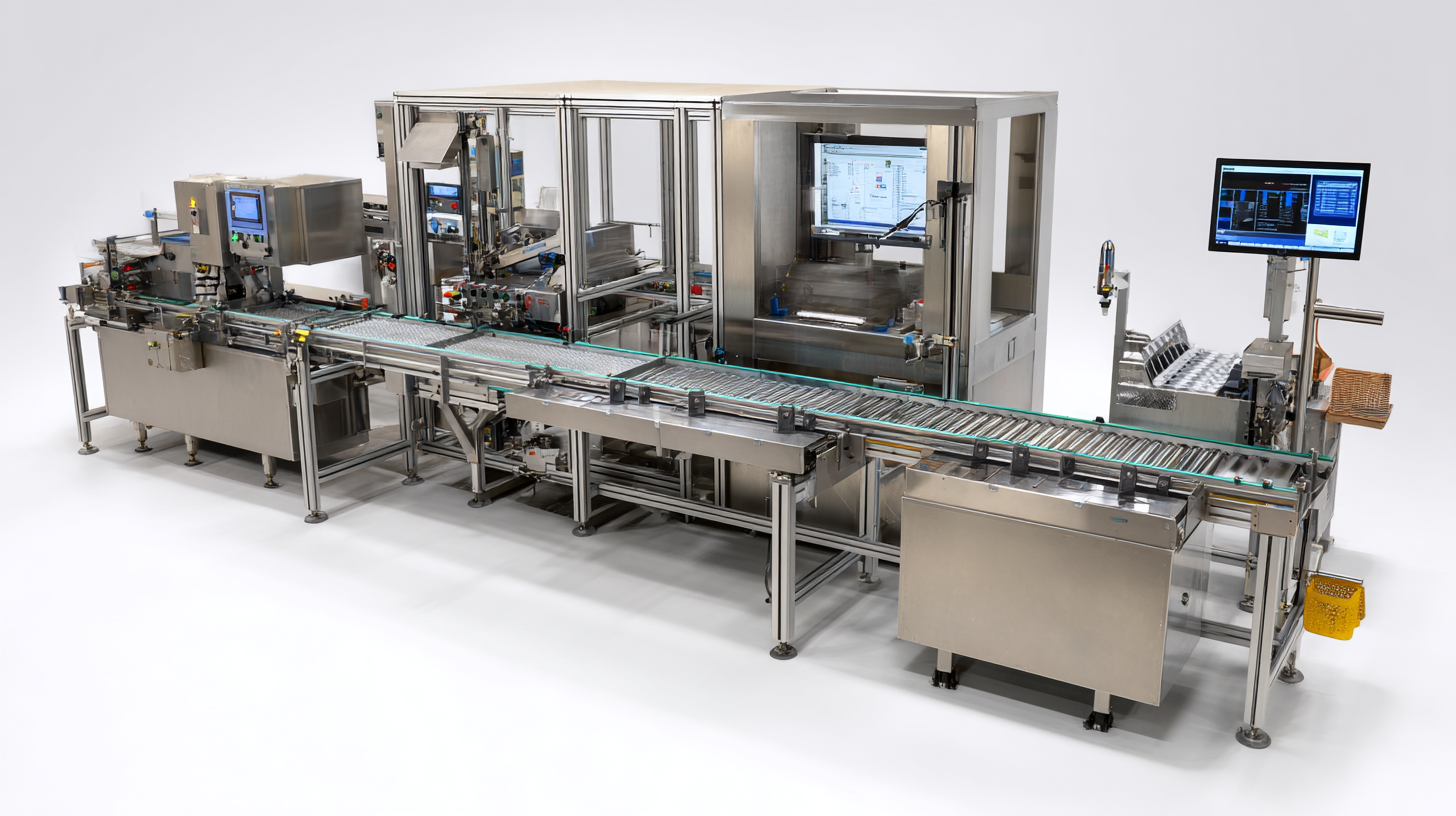

Integrating dynamic checkweighers into your production workflow can significantly enhance operational efficiency and accuracy. To begin with, it’s essential to assess the specific needs of your production line; understanding the type of products being weighed, their sizes, and weight variations will help you choose the right checkweigher. Establishing clear goals, such as desired accuracy levels and throughput rates, ensures that you select a machine that fits seamlessly into your existing system.

Once you have selected an appropriate dynamic checkweigher, training staff on its operation and maintenance is critical. This ensures that employees can effectively monitor the system, address any issues that arise, and optimize performance over time. Additionally, integrating the checkweighers with other systems—such as data analytics platforms—can provide real-time insights into production processes, allowing for timely adjustments and maintaining the desired accuracy of 99.5%. Regularly reviewing and refining these integrations will keep your production line agile and responsive to changing demands.

Dynamic checkweighers are indispensable tools in modern production lines, particularly for businesses aiming to enhance product accuracy to an impressive 99.5%. Their advanced technology facilitates real-time weight measurements, which minimizes the risk of overfilling or underfilling products. According to a recent report by the International Society of Automation, incorporating dynamic checkweighers can lead to a 20% reduction in product giveaway, significantly improving operational efficiency and cost-effectiveness.

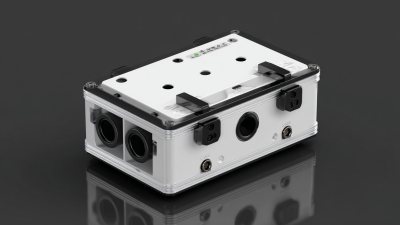

Key features of dynamic checkweighers include high-speed data processing, integrated software for precise control, and adaptability to various production environments. Many models come equipped with advanced sensors that detect minute weight changes within milliseconds, ensuring that even the smallest discrepancies are addressed instantly. Moreover, the ability to connect to factory management systems allows for seamless data integration and monitoring, enhancing overall production accuracy.

Key features of dynamic checkweighers include high-speed data processing, integrated software for precise control, and adaptability to various production environments. Many models come equipped with advanced sensors that detect minute weight changes within milliseconds, ensuring that even the smallest discrepancies are addressed instantly. Moreover, the ability to connect to factory management systems allows for seamless data integration and monitoring, enhancing overall production accuracy.

Tips:

To maximize the benefits of dynamic checkweighers, calibrate them regularly to accommodate for variations in product weight and environmental conditions. Additionally, train staff to interpret the data provided by these machines effectively, ensuring informed decision-making that bolsters product quality. Finally, consider investing in checkweighers that offer scalability, enabling you to adjust your setup as production demands evolve.

Dynamic checkweighers have become crucial tools for optimizing production lines, significantly improving accuracy. To leverage their capabilities for continuous improvement, analyzing the data collected by these systems is essential. By implementing data analysis techniques, businesses can uncover insights that drive efficiency and quality enhancements in their operations.

**Tips:** One effective approach is to establish a routine for reviewing checkweigher data, which can pinpoint inefficiencies or inconsistencies in the production process. Consider integrating real-time dashboards that visualize data trends and anomalies, enabling quick decision-making. This not only fosters a proactive management style but also helps in maintaining high-quality standards.

Additionally, organizations should foster a culture of data-driven decision-making. Equip teams with training on data interpretation and actionable insights derived from checkweigher performance. This empowers staff to contribute to ongoing optimization efforts actively, thus enhancing overall productivity. Remember, the ultimate goal is not just to collect data but to translate it into meaningful actions that promote continuous improvement across the production line.

Dynamic checkweighers play a crucial role in maintaining the efficiency and accuracy of production lines. However, several common challenges can hinder their effectiveness. One prevalent issue is the variability in product weight due to inconsistent ingredient measurements or fluctuating environmental conditions. This can lead to incorrect weight readings, resulting in rejected products and wasted resources. To tackle this challenge, it is vital to implement standardized measurement protocols and invest in training for staff to ensure uniformity in product formulation.

Dynamic checkweighers play a crucial role in maintaining the efficiency and accuracy of production lines. However, several common challenges can hinder their effectiveness. One prevalent issue is the variability in product weight due to inconsistent ingredient measurements or fluctuating environmental conditions. This can lead to incorrect weight readings, resulting in rejected products and wasted resources. To tackle this challenge, it is vital to implement standardized measurement protocols and invest in training for staff to ensure uniformity in product formulation.

Another significant challenge is the calibration of the checkweigher itself. Frequent adjustments may be necessary to maintain accuracy, especially in high-speed production environments where changes in the line speed can affect performance. Experts recommend regularly scheduled maintenance and calibration checks to preemptively address any discrepancies. Additionally, utilizing advanced data analytics can help identify patterns and trends that may indicate when recalibration is required, further enhancing the reliability of the checkweighers in ensuring that products meet quality standards.

Dynamic checkweighers represent a pivotal advancement in production line efficiency, particularly when it comes to maximizing return on investment (ROI). By integrating these systems, businesses can significantly streamline their operations while maintaining an impressive accuracy rate of 99.5%. This level of precision not only minimizes product overfill and underfill but also ensures compliance with industry standards, thereby reducing the risk of costly legal penalties and product recalls.

The cost-benefit analysis of implementing dynamic checkweighers goes beyond mere accuracy. The initial investment can be offset by decreased material waste and improved resource allocation. By optimizing weight measurement in real-time, companies can enhance their production rates, reduce downtime, and ultimately increase profits. Furthermore, the data gathered from these systems provides valuable insights into production patterns, allowing for continuous improvement and strategic decision-making that fuels long-term growth and sustainability in a competitive market.

| Parameter | Value Before Implementation | Value After Implementation | Improvement (%) | Estimated Annual ROI ($) |

|---|---|---|---|---|

| Production Accuracy | 95% | 99.5% | 4.5% | $150,000 |

| Waste Reduction | 10% | 2% | 80% | $75,000 |

| Production Speed | 200 units/hour | 250 units/hour | 25% | $100,000 |

| Labor Costs | $300,000 | $240,000 | 20% | $60,000 |

| Total Estimated ROI | $385,000 | |||