In today's fast-paced world, optimizing equipment for peak performance is essential, and the Mandarin Sorting Machine is no exception. As organizations across various sectors increasingly rely on automation to enhance productivity, understanding how to maximize the efficiency of this sophisticated machinery becomes crucial.

This guide will delve into practical strategies and tips to ensure that your Mandarin Sorting Machine operates at its full potential. From fine-tuning settings to streamlining workflows, every aspect plays a significant role in achieving operational excellence. By implementing the techniques discussed here, businesses can not only improve sorting accuracy but also decrease downtime and increase throughput, ultimately leading to higher profitability and better service delivery.

Join us as we explore the key methods to elevate the performance of your Mandarin Sorting Machine to new heights.

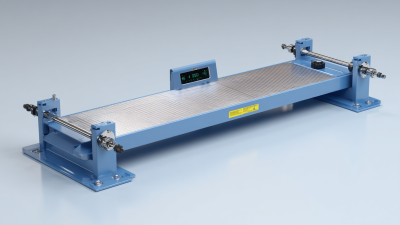

Mandarin sorting machines are crucial in ensuring the quality and efficiency of citrus processing. The key components of these machines include sorting belts, vision systems, and grading mechanisms, each playing a significant role in maintaining high operational standards. The sorting belts are responsible for transporting mandarins through various stages, allowing for thorough inspection and classification. The material and design of these belts can influence the speed and accuracy of sorting, making them fundamental for optimizing performance.

Vision systems, often integrated with artificial intelligence, enable precise identification of fruit size, color, and imperfections. This technology reduces human error and enhances speed, leading to improved productivity. Grading mechanisms, which categorize mandarins based on predetermined standards, ensure that only the highest quality fruits reach consumers. Proper calibration and maintenance of these components directly affect the efficiency of the sorting process, minimizing waste and maximizing yield. By focusing on these critical elements, operators can significantly enhance the effectiveness of their mandarin sorting machines.

To optimize a Mandarin sorting machine for maximum efficiency, it's essential to start with a solid understanding of sorting algorithms specific to Mandarin grade and quality. Different sorting algorithms, such as bubble sort, quicksort, and merge sort, can significantly impact the speed and effectiveness of categorizing Mandarins. For instance, quicksort is generally faster for large datasets, allowing for rapid comparison and sorting of fruit based on factors like size, color, and blemish presence.

Additionally, incorporating machine learning into the sorting process can enhance the accuracy of categorizing Mandarins into different grades. By training a model on labeled images of Mandarins, the sorting machine can learn to identify subtle differences in quality that traditional algorithms might miss. This technology can optimize the sorting process by minimizing human error and increasing throughput, ensuring that only the highest quality fruit reaches consumers. Understanding and implementing these advanced sorting algorithms will be crucial for any grower looking to improve their Mandarin sorting efficiency.

Regular maintenance is essential for enhancing the longevity of your Mandarin sorting machine. One of the most critical practices is routine cleaning. Accumulated debris and dust can affect the machine's performance, leading to inaccurate sorting or mechanical failures. Implementing a scheduled cleaning protocol will not only keep the machine hygienic but also improve its operational efficiency. Use appropriate cleaning agents that do not harm the machinery’s sensitive components, and ensure that all areas of the machine, including the conveyor belts and sorting trays, are thoroughly inspected and maintained.

Regular maintenance is essential for enhancing the longevity of your Mandarin sorting machine. One of the most critical practices is routine cleaning. Accumulated debris and dust can affect the machine's performance, leading to inaccurate sorting or mechanical failures. Implementing a scheduled cleaning protocol will not only keep the machine hygienic but also improve its operational efficiency. Use appropriate cleaning agents that do not harm the machinery’s sensitive components, and ensure that all areas of the machine, including the conveyor belts and sorting trays, are thoroughly inspected and maintained.

Additionally, regular lubrication of moving parts plays a crucial role in maintaining the machine’s efficiency. Dry bearings or gears can lead to increased friction, resulting in wear and tear. Establish a maintenance schedule that includes the application of suitable lubricants to all designated areas, referring to the manufacturer's guidelines for frequency and type of lubrication required. This practice will minimize mechanical resistance and extend the life of your sorting machine, ultimately leading to greater productivity and reduced downtime for repairs. By prioritizing these maintenance practices, you can ensure your Mandarin sorting machine operates at peak performance for years to come.

To optimize your Mandarin sorting machine for maximum efficiency, leveraging technology through software upgrades is essential. Recent developments in various industries highlight the significance of continual software enhancements. For instance, a company recently received certification for its software upgrade management system, demonstrating the importance of compliance and innovation in maintaining an efficient operation. Upgrading the software not only increases performance but also ensures that systems are aligned with the latest technological standards, paving the way for more robust capabilities.

Tips: Focus on implementing regular software updates to enhance the performance of your sorting machine. Schedule these updates to occur during off-peak hours to minimize disruption. Additionally, analyze the latest software solutions that offer intelligent data integration, which can optimize sorting processes through improved algorithms.

Moreover, using advanced software can provide analytics that empower operators to make data-driven decisions. Monitoring machine performance in real-time can uncover inefficiencies, allowing for immediate rectifications. Emphasizing the importance of software in your optimization strategy is crucial, as technology continues to evolve rapidly, offering new opportunities for enhanced efficiency.

To optimize the efficiency of your Mandarin sorting machine, implementing robust data analysis techniques is crucial. According to a report by MarketsandMarkets, the global market for agricultural sorting machines is expected to reach $2.17 billion by 2025, highlighting the increasing need for efficiency in sorting operations. By leveraging data analytics, operators can continually monitor performance metrics such as sorting speed, accuracy, and machine downtime. These insights can lead to timely adjustments in sorting parameters, ultimately enhancing operational productivity.

A key aspect of data analysis involves employing machine learning algorithms to predict maintenance needs and prevent equipment failures. A study from McKinsey & Company indicated that predictive maintenance can reduce machine downtime by up to 50%, significantly improving overall sorting efficiency. By utilizing historical data on machine performance, companies can forecast when maintenance should be performed before issues arise, ensuring that the sorting process remains uninterrupted and efficient. Moreover, real-time data dashboards can help operators make informed decisions on the fly, optimizing workflows and resource allocation in the sorting facility.