In today's fast-paced manufacturing and packaging environments, the integration of Checkweigher Online solutions has become crucial for enhancing operational efficiency. Recent industry reports indicate that nearly 70% of manufacturers are investing in automated weighing systems to meet escalating quality control standards and reduce product waste. With the rising demand for precision in product measurement, companies leveraging online checkweighing technology can experience up to a 30% increase in productivity by streamlining their processes. Furthermore, these advanced solutions not only ensure compliance with weight regulations but also provide real-time data analytics that empower decision-makers to optimize workflows. In this blog, we will explore five essential tips for maximizing efficiency with Checkweigher Online solutions, enabling organizations to stay competitive in a rapidly evolving market.

In the era of rapid technological advancement, understanding the basics of checkweigher online solutions is vital for enhancing operational efficiency. As businesses increasingly adopt digital tools, a recent study indicates that 82% of organizations are now leveraging online systems to monitor production metrics more effectively. The implementation of checkweighers can significantly streamline processes by ensuring product quality and compliance with weight regulations. This real-time monitoring capability not only minimizes errors but also aids companies in adhering to industry standards, ultimately boosting consumer trust.

Furthermore, the integration of innovative technologies such as artificial intelligence and cloud computing is reshaping the landscape of checkweigher applications. A report highlights that businesses utilizing AI-powered analytics can reduce operational costs by up to 30%. This is achieved through improved data processing and predictive maintenance, which enhances the reliability of checkweighers. Moreover, cloud accounting’s rise, with its ability to sync data across platforms, empowers firms to make informed decisions swiftly, driving efficiency. As the industry continues its digital transformation, investing in online solutions for checkweighing is no longer optional but essential for maintaining a competitive edge.

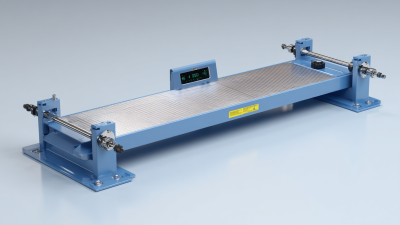

Integrating checkweigher systems into your production line can significantly enhance operational efficiency and product compliance. Recent reports indicate that manufacturers who employ automated checkweighers can achieve up to a 20% reduction in waste due to improved accuracy in weight measurements. This precision not only minimizes the risks associated with under- or overfilling products but also ensures compliance with industry regulations, which is critical for maintaining customer trust.

Seamless integration of checkweigher solutions involves aligning the systems with existing production workflows. This is essential as studies have shown that nearly 30% of production slowdowns are attributed to the misalignment of equipment. By utilizing flexible checkweigher models equipped with advanced software, companies can more effectively monitor real-time data and adjust their operations dynamically. This adaptability can lead to a substantial decrease in downtime, facilitating a smoother production flow and ultimately boosting the bottom line. Leveraging these technologies will undoubtedly prepare manufacturers to meet the increasing demands of the market while maintaining high-quality standards.

In the fast-paced world of manufacturing and packaging, real-time monitoring of weighing processes has become crucial for maximizing efficiency and ensuring product quality. Implementing checkweigher online solutions allows companies to analyze data swiftly, enabling quick adjustments to production lines. According to a recent study by the Food and Beverage Sector, utilizing advanced checkweighing technology can improve operational efficiency by up to 30%. This efficiency is largely attributed to the immediate feedback systems that identify discrepancies in weight, thus minimizing waste and reducing the time spent on manual inspections.

Furthermore, integrating data analytics into checkweighing offers companies the ability to monitor trends and make informed decisions. A report from the International Society of Automation highlights that organizations employing real-time data analysis can reduce product recalls by as much as 25%, as discrepancies can be addressed instantly before reaching the market. By leveraging online checkweigher solutions, manufacturers not only enhance their accuracy but also gain invaluable insights into their weighing processes, ultimately leading to improved compliance and customer satisfaction.

When selecting checkweigher software, certain key features can significantly enhance performance and operational efficiency. One of the most critical aspects to consider is real-time data processing capabilities. According to a report by MarketsandMarkets, the global checkweigher market is projected to reach $600 million by 2025, indicating a growing reliance on precise weight measurement and data analysis for streamlined operations. Software that integrates real-time data allows operators to immediately identify discrepancies, reduce product loss, and optimize workflow.

Another essential feature is user-friendly interfaces paired with robust reporting tools. A survey conducted by the International Society of Automation revealed that 70% of manufacturing professionals prioritize usability in software to minimize training time and reduce errors. Programs that offer customizable dashboards and intuitive navigation can enable staff to monitor operations efficiently, ensuring adherence to regulatory standards and improving overall productivity. Ensuring your checkweigher software has these vital components will lead to enhanced operational insights and better decision-making processes.

Training your team to effectively utilize checkweigher technology is crucial for maximizing output in manufacturing environments. A report by the Food and Beverage Manufacturing Industry shows that companies implementing advanced checkweigher systems have improved their production line efficiency by up to 25%. This increase is largely attributed to reduced downtime from product rejections and better compliance with weight regulations. With proper training, employees can quickly identify potential issues in the production process, enabling them to take corrective action before significant problems arise.

Moreover, ongoing training sessions can equip teams with the skills necessary to interpret the data generated by checkweigher systems. According to a study by the International Society for Automation, organizations that effectively utilize real-time data analysis can enhance their operational efficiency by as much as 30%. By fostering a culture of continuous learning, businesses can empower their staff to leverage this technology fully, leading to smarter decision-making and improved productivity on the shop floor. Regular workshops and updates about advancements in checkweigher technology ensure that your team remains adept, ultimately driving optimal performance and ROI.

This chart illustrates the efficiency improvements observed in key areas after training teams to effectively utilize checkweigher technology. The data represents the percentage increase in output across various departments over a six-month period.