In the ever-evolving landscape of industrial automation, optimizing operational efficiency is crucial for maintaining competitiveness. One vital component in this equation is the Belt Counterweight Scale, a device that plays a significant role in ensuring accurate weight measurements and proper load distribution. According to industry reports, inefficiencies in material handling can lead to a staggering 20% increase in operational costs (American Society of Mechanical Engineers, 2021). Consequently, adopting innovative solutions for Belt Counterweight Scale efficiency is not merely beneficial but essential. By implementing advanced technologies and best practices, industries can enhance their productivity and reliability while minimizing errors associated with weight measurements. This blog will explore a comprehensive checklist approach that outlines key strategies, technologies, and best practices designed to optimize the performance of Belt Counterweight Scales in various industrial applications.

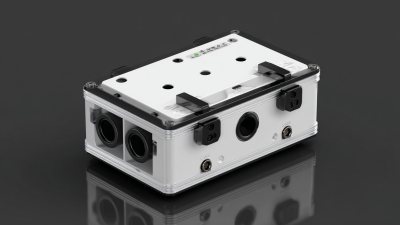

In recent years, innovative technologies have significantly enhanced the functionality of industrial belt counterweight scales, transforming how organizations measure and manage their processes. Advanced sensors coupled with smart algorithms now allow for real-time monitoring and adjustments, ensuring accurate weight measurements under varying environmental conditions. This means operational efficiency is greatly improved, as businesses can mitigate errors that were previously common in traditional scales.

Moreover, the integration of IoT (Internet of Things) capabilities enables seamless communication between scales and central management systems. Data collected from belt counterweight scales can now be analyzed for trends and anomalies, facilitating proactive maintenance and reducing downtime. By leveraging machine learning, companies can optimize their processes further, making adjustments on-the-fly based on the data insights received. These advancements don't just streamline operations; they also contribute to enhanced safety and sustainability by minimizing waste and improving resource utilization in industrial settings.

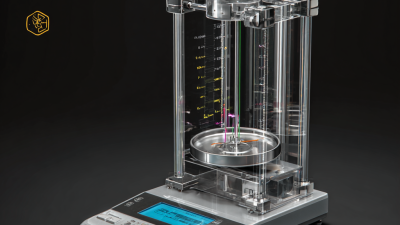

In the realm of industrial belt counterweight scale systems, efficiency hinges on several key factors that warrant careful consideration. First and foremost, the accuracy of load cell calibration plays a pivotal role. According to a recent report by the International Journal of Industrial Automation, improperly calibrated load cells can lead to a 5% decrease in overall efficiency, significantly impacting operational costs. Regular maintenance and recalibration schedules must be implemented to ensure optimal performance.

Another critical factor is the quality and type of materials used in the counterweight system itself. A study published by the American Society of Mechanical Engineers highlights that using high-density materials can increase the longevity and precision of scale readings by up to 15%. Ensuring these systems are constructed with durable and suitable materials can mitigate wear and tear, ultimately enhancing efficiency.

Tip: Regularly monitor and replace any worn components in your belt counterweight system to maintain high operational standards.

Finally, the integration of advanced technology, such as real-time data analytics and automated reporting tools, can drastically improve efficiency. Research indicates that companies employing such technologies have seen an efficiency boost of 20%, allowing for proactive decision-making and maintenance schedules.

Tip: Invest in software solutions that provide comprehensive data analysis to help fine-tune your operational processes.

Implementing effective counterweight scale solutions in industrial settings is essential for optimizing operational efficiency and accuracy. One of the best practices is to conduct a thorough assessment of the existing weighing systems. This evaluation should identify performance gaps and areas where traditional methods may fall short. Incorporating advanced technology, such as load cells with higher precision and digital displays, can significantly improve the reliability of measurements. Regular calibration and maintenance routines are also crucial to ensure the scales function optimally, which ultimately contributes to more accurate inventory management and reduced operational costs.

Another key practice is to train personnel on the importance of counterweight scale efficiency. Employees should understand how accurate measurements impact productivity and quality control. By fostering a culture of awareness and accountability, organizations can minimize human errors, which are often a leading cause of discrepancies in weight measurement. Additionally, providing access to user-friendly interfaces and automated reporting systems can streamline the weighing process and enhance user engagement, leading to better decision-making based on real-time data. Implementing these practices not only boosts efficiency but also supports a sustainable approach to industrial operations.

| Parameter | Value | Unit | Comments |

|---|---|---|---|

| Weight Capacity | 5000 | kg | Maximum load handled by system |

| Accuracy | ±0.5 | % | Measurement accuracy |

| Speed of Operation | 30 | cm/s | Speed during weighing process |

| Calibration Interval | 6 | months | Recommended calibration frequency |

| Installation Time | 2 | days | Average time for system setup |

| Maintenance Frequency | Quarterly | Recommended routine checkups |

In today's industrial environment, optimizing belt counterweight scales is crucial for enhancing operational efficiency. A recent case study highlights a leading manufacturing company that implemented a novel scaling technique, integrating advanced load cell technology. By utilizing real-time data analytics, they were able to monitor weight variations more accurately, resulting in minimized downtime and improved material handling processes. This innovative approach showcases how embracing new technologies can transform traditional practices in industrial settings.

Another compelling example comes from the mining sector, where a company deployed a custom-designed counterweight scale system that utilized smart sensors and automated calibration. This initiative not only streamlined their loading operations but also significantly reduced errors in weight measurements, leading to better compliance with regulations and increased profitability. The successful application of these innovative scaling techniques demonstrates the potential for industries to enhance performance through strategic technological investments.

As the industrial sector continues to evolve, the design and efficiency of belt counterweight scales are becoming increasingly crucial. Future trends indicate that advancements in materials and integration of technology will play significant roles in enhancing performance. Recent reports predict robust growth in related markets, such as the weight vest market, anticipated to grow from USD 205 million in 2024 to USD 350 million by 2033, showcasing a CAGR of 6.5%. This growth reflects a broader trend towards innovative solutions that improve efficiency across various domains, including industrial applications.

One key trend is the optimization of mechanical power transmission, notably through industrial V belts. These belts play an essential role in enhancing operational efficiency by minimizing energy loss during power transfer. As industries gear towards sustainability and cost reduction, the integration of advanced composite materials will also gain traction. Such materials not only provide strength but also reduce weight, greatly benefiting the design and durability of counterweight scales.

Tips: When considering upgrades, focus on selecting materials that enhance durability without compromising weight efficiency. Additionally, investing in technology that monitors real-time performance can lead to significant improvements in operational effectiveness. Embracing these innovations will pave the way for improved productivity and reduced long-term costs in the industrial sector.