The Rotary Collecting Table Machine is a pivotal tool in many manufacturing processes. It streamlines operations and enhances productivity. Understanding its features is crucial for optimal use.

Many users face challenges when starting. The setup can be daunting, and minor misalignments can lead to inefficiencies. Additionally, regular maintenance is often overlooked. This can result in machine failures that halt production.

By addressing these common pitfalls, operators can enhance their skills. It’s essential to learn from mistakes and seek improvements in every operation. Embracing the details of the Rotary Collecting Table Machine can lead to significant gains in efficiency and output.

When exploring rotary collecting table machines, it's vital to understand their fundamental components. These machines often consist of a rotating platform, which collects items as they move through the production process. Operators should carefully monitor the alignment of items on the table. Misalignments can cause inefficiencies and disrupt production flow. Little adjustments can make a big difference.

Operating these machines requires a keen eye and experience. Beginners may find it challenging to maintain optimal speed and rotation. It's not just about turning a knob; understanding weight distribution matters. Imbalances can lead to unexpected spills or jams. As operators gain experience, they will learn the delicate balance needed to keep everything running smoothly.

Regular maintenance is key. Small issues, if ignored, can escalate into costly repairs. It's easy to overlook minor wear and tear on components, yet this can lead to machine downtime. Operators should schedule frequent inspections. They will become familiar with the machine's quirks over time. This familiarity can help in anticipating potential problems before they arise.

Rotary collecting table machines are essential in many industries. They streamline processes by organizing and directing materials efficiently. Key components of these machines include the drive system, collection area, and control panel. The drive system provides the necessary movement. It can vary in complexity, affecting efficiency.

The collection area is where materials gather. This section's design significantly impacts the machine's overall performance. For instance, a shallow collection area may lead to frequent jams. According to a recent industry report, machines with optimized collection areas increase efficiency by up to 30%.

Control panels are where operators interact with the machine. They can range from basic to advanced interfaces. The choices made here affect user experience. Poorly designed panels can cause confusion and slow down production. A report highlighted that training operators on effective use can boost productivity by 25%. Not addressing these aspects can leave room for improvement. In rotary collecting table machines, even minor tweaks can lead to substantial gains.

Operating a rotary collecting table demands precision and careful attention. To start, ensure the tabletop is aligned correctly. Misalignment can cause jammed components or uneven distribution of items. Regularly check the table for debris. Even small particles can disrupt operation and lead to costly downtime.

Another key aspect is monitoring the speed settings. Too high a speed may create instability, while too low can result in inefficiencies. Experiment with different speeds to find the optimal setting for your materials. Maintaining a consistent feed rate is also essential. Variations can lead to bottlenecks or mishandling, impacting overall workflow.

Remember, no system is perfect. Regularly revisiting your operational techniques can reveal areas for improvement. Analyze production data to identify patterns or recurring issues. Employee feedback can also provide valuable insights. Allowing for adjustments will enhance the efficiency of your rotary collecting table. Engaging with the team about these challenges fosters a collaborative approach to problem-solving.

Regular maintenance is essential for maximizing the lifespan of your rotary collecting table machine. Cleanliness is key. Dust and debris can settle in crucial areas, leading to wear and tear. Check the machine’s components weekly, and use compressed air to blow out any buildup. Keep the working area free from clutter as well. Even a small object can cause significant damage if caught in the machine.

Lubrication also plays a vital role. Apply the recommended lubricant to moving parts, but avoid over-lubricating. Too much lubricant can attract dirt and reduce efficiency. Schedule lubrication every month to maintain optimal performance. Replace any worn-out parts promptly. Ignoring small issues can lead to bigger problems down the line.

Make sure to monitor the machine’s performance regularly. Listen for unusual noises; they often signal problems. If something feels off, inspect it immediately. It’s crucial to train all users on proper operation and maintenance techniques. Mistakes happen, and a lack of knowledge can shorten the machine's life.

| Tip | Details | Frequency | Benefits |

|---|---|---|---|

| Clean Regularly | Remove dust and debris from the machine | Weekly | Prevents wear and improves efficiency |

| Lubricate Moving Parts | Apply appropriate lubricants to all moving components | Monthly | Reduces friction and extends machine life |

| Check Electrical Connections | Inspect and tighten any loose electrical connections | Quarterly | Enhances safety and prevents electrical failures |

| Inspect Table Flatness | Use a level to check the flatness of the rotary table | Bi-Annually | Ensures precision in operations |

| Replace Worn Parts | Regularly check and replace any worn or damaged components | As needed | Maintains functionality and prevents breakdowns |

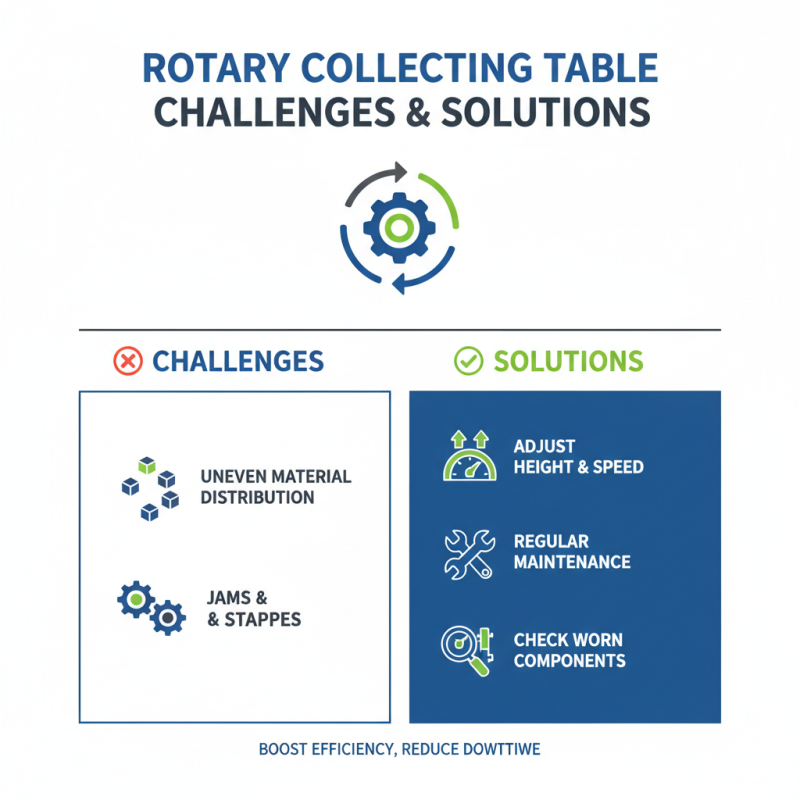

Rotary collecting tables can enhance efficiency, but they often encounter challenges. Operators may notice uneven distribution of materials. This imbalance can lead to jamming issues. Adjusting the height and speed settings can help alleviate these problems. Regular maintenance is crucial. Check for worn-out components that might affect performance.

Another common issue is the accumulation of debris. Dust and particles can obstruct the mechanism, causing delays. Cleaning the table regularly can prevent operational disruptions. It’s essential to use the right cleaning materials. Some might use harsh chemicals that damage delicate parts.

Occasionally, the alignment of the collecting table may shift. Misalignment can cause materials to be improperly collected. Operators should routinely verify the setup. A small deviation might lead to significant production inefficiencies. Recording operational inconsistencies can provide insights for future improvements.