In the rapidly evolving landscape of manufacturing and quality control, the role of technology in enhancing efficiency and accuracy has never been more crucial. One such innovation that has garnered significant attention is the Metal Detector Checkweigher. As we look towards 2025, the integration of advanced alternatives in Metal Detector Checkweigher systems promises to revolutionize how industries detect contaminants and ensure product compliance. This blog will explore the latest innovations in this field, highlighting various alternatives that enhance detection capabilities, streamline operations, and improve overall product safety. From cutting-edge sensors to smart software solutions, we will navigate the future of Metal Detector Checkweighers and unveil the transformative potential these innovations hold for businesses striving to meet the highest standards in their operations. Join us on this journey as we uncover the trends shaping the future of industrial quality control.

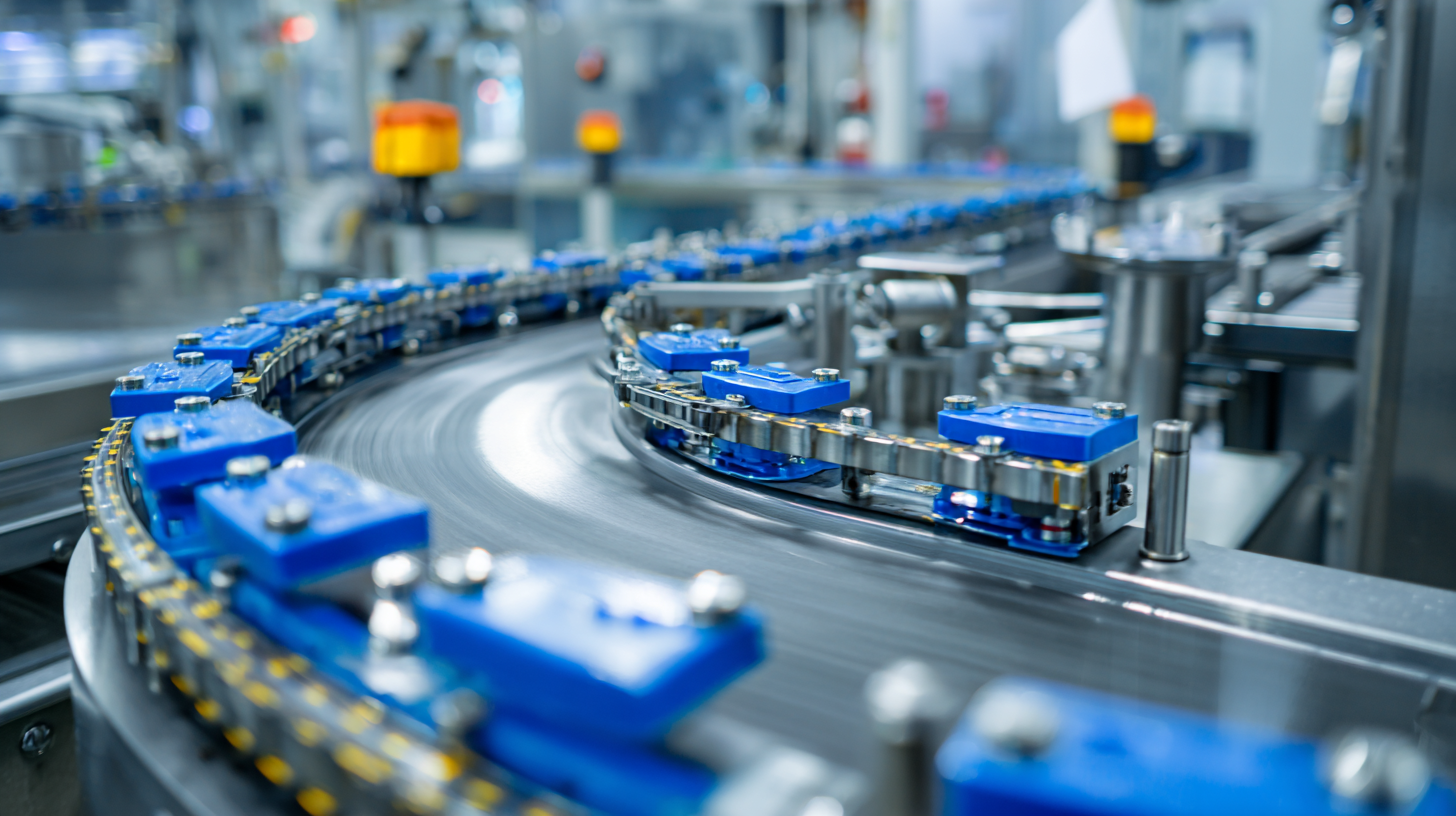

In 2025, revolutionary innovations in metal detector technologies are poised to reshape the landscape of checkweighing practices across various industries. As businesses increasingly prioritize food safety and quality control, the integration of metal detection and checkweighing into a single system is becoming more prevalent. This not only simplifies the inspection process but also enhances the efficacy of product safety measures. The latest systems are designed for smart operation, ensuring that contaminants are detected efficiently while maintaining precision in weight assessment.

The new breed of combination checkweighers is engineered to minimize downtime associated with cleaning and maintenance. These advancements are critical, as industries face growing demands for efficiency without compromising on safety. The melding of superior sensitivity in metal detection with accurate weighing capabilities enhances overall product inspection processes, allowing companies to streamline their operations effectively. As the food industry continues to innovate, these technologies will undoubtedly play a vital role in maintaining high standards of safety and quality.

As we approach 2025, the advancements in metal detector checkweighers are poised to revolutionize industries that prioritize safety and efficiency. When considering the next generation of these devices, several key features will stand out. First and foremost, enhanced sensitivity is critical. Next-gen models will incorporate advanced detection technology, allowing for the identification of even the smallest metal contaminants, thereby reducing the risk of product recalls and ensuring compliance with stringent safety regulations.

Another noteworthy feature will be integration with smart technology. Future metal detector checkweighers will leverage Internet of Things (IoT) capabilities, enabling real-time data analytics and remote monitoring. This will facilitate quicker decision-making and improve overall operational efficiency. Additionally, user-friendly interfaces will become standard, allowing operators to efficiently manage settings and review detection performance without extensive training. The focus on sustainability is also expected to increase, with designs that prioritize energy efficiency and reduced waste, aligning with global efforts toward greener manufacturing practices.

As we move into 2025, the integration of AI and machine learning in metal detection technologies is set to revolutionize the industry. These advanced technologies enhance the accuracy of metal detectors by leveraging vast amounts of data to learn from various metal attributes and environments. Unlike traditional detectors, which often rely on preset parameters, AI-powered systems adapt in real-time, improving their ability to discern between metal contaminants and product materials. This adaptability not only increases detection rates but also minimizes false positives, significantly streamlining quality control processes.

Moreover, machine learning algorithms can continuously refine their detection capabilities as they collect data from each scan. This facilitates predictive maintenance, allowing systems to identify potential issues before they lead to operational downtime. Additionally, AI can analyze patterns over time, offering insights into common contamination sources and helping manufacturers take proactive measures. By embracing these innovations, companies will not only enhance their metal detection accuracy but also drive efficiencies across their production lines, ensuring higher safety standards and compliance in various industries.

As we look forward to 2025, the checkweigher industry is witnessing a transformative shift towards sustainability. Eco-friendly innovations are becoming a focal point in design, with manufacturers increasingly prioritizing materials that minimize environmental impact. This commitment not only reduces waste but also enhances the overall efficiency of operations. For businesses, investing in sustainable checkweighers means aligning with global efforts to reduce carbon footprints, which is becoming more critical for compliance and brand reputation.

When choosing a checkweigher, consider selecting models that utilize recycled materials and energy-efficient technology. This can significantly reduce the operational costs while also showcasing your company’s commitment to sustainability. Additionally, explore options that feature modular designs, allowing for upgrades without complete replacements, which further contributes to reducing waste.

To ensure the longevity and efficiency of your equipment, regular maintenance is essential. Implement a preventive maintenance schedule that focuses not only on the technical aspects but also on optimizing the eco-friendly components of your checkweigher systems. This proactive approach not only preserves the equipment but also enhances its performance in an environmentally responsible manner.

As industries continue to evolve, the importance of adhering to emerging metal detection standards has become paramount for businesses keen on future-proofing their operations. According to a report by MarketsandMarkets, the global metal detection market is projected to reach $4.2 billion by 2025, driven largely by increased regulatory scrutiny and the demand for product safety in sectors such as food and pharmaceuticals. In this context, metal detector checkweighers are not merely quality assurance tools but essential components of a comprehensive compliance strategy.

The latest innovations in metal detector checkweighers are designed to enhance both accuracy and efficiency. For instance, integrating advanced software with machine learning capabilities allows for real-time detection and correction, significantly reducing false rejects and improving line productivity. A study published by the Food Industry Association indicates that businesses implementing these advanced systems can experience up to a 30% reduction in product waste, thus ensuring not only compliance with stringent safety standards but also better profit margins. Adapting to these innovations will be critical as manufacturers seek to stay ahead in a competitive landscape that demands both quality and accountability.

This chart illustrates the projected investments in various areas of metal detector checkweigher innovations for the year 2025. It highlights where companies are focusing their resources to enhance their operations and adapt to emerging standards in metal detection technology.