The Belt Counterweight Scale plays a crucial role in various industrial applications by ensuring optimal performance and safety in bulk material handling. According to a recent report published by the International Journal of Industrial Automation, proper weight measurement in conveyor systems can enhance operational efficiency by up to 20%. The scale helps maintain the correct tension of the conveyor belts, preventing slippage and reducing maintenance costs associated with equipment wear and tear.

Moreover, it ensures that the materials transported meet regulatory standards, thereby minimizing risks of overload and potential accidents. As industries increasingly adopt automation and strive for precision in their operations, the demand for reliable weighing solutions like the Belt Counterweight Scale is projected to grow significantly, presenting an opportunity for improved productivity and cost savings in the long run.

Moreover, it ensures that the materials transported meet regulatory standards, thereby minimizing risks of overload and potential accidents. As industries increasingly adopt automation and strive for precision in their operations, the demand for reliable weighing solutions like the Belt Counterweight Scale is projected to grow significantly, presenting an opportunity for improved productivity and cost savings in the long run.

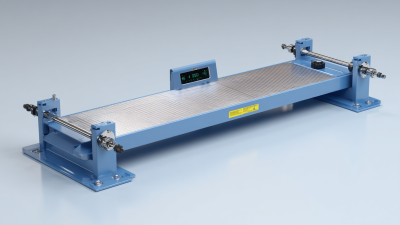

Belt counterweight scales are essential tools in various industrial applications, primarily focused on accuracy and efficiency in measuring weight. These systems operate by utilizing a counterweight mechanism, which helps maintain balance and precise readings, especially in environments where heavy loads are common. Understanding the functioning of these scales is crucial for industries relying on exact weight measurements, ensuring both safety and optimal performance.

In essence, a belt counterweight scale comprises a conveyor belt system equipped with a weighing module. As materials are transported along the belt, the scale continuously monitors their weight. The counterweight adjusts to compensate for any fluctuations, providing a stable and accurate measurement. This technology is particularly beneficial in sectors such as mining, agriculture, and manufacturing, where bulk materials need to be weighed for inventory and processing purposes. By leveraging the capabilities of belt counterweight scales, businesses can significantly improve their operational efficiency and reduce the risk of errors in weight measurements.

| Dimension | Description | Application Area | Benefits |

|---|---|---|---|

| Weight Measurement | Accurately measures the weight of materials on a conveyor belt. | Mining, construction, and bulk material handling. | Improves operational efficiency and product tracking. |

| Dynamic Modelling | Utilizes real-time data to adjust counterweights based on load. | Food processing and packaging industries. | Reduces wear and tear on equipment. |

| Counterweight Adjustment | Balances the belt for optimal performance. | Automotive supply chains. | Ensures consistent operation and reduces downtime. |

| Load Cells | Sensors that detect weight and send data to the control system. | Recycling and waste management facilities. | Enhances data accuracy for inventory control. |

| Integration with Control Systems | Works with other systems for comprehensive monitoring. | Manufacturing automation. | Streamlines processes and improves decision-making. |

Belt counterweight scales play a crucial role in various industrial applications, particularly in ensuring accurate weight measurement for bulk materials. One of the key benefits of using these scales is their ability to enhance operational efficiency. According to a report by the Material Handling Industry, utilizing advanced weighing solutions like belt counterweight scales can lead to a 15-20% increase in productivity by minimizing material loss and improving inventory management.

Belt counterweight scales play a crucial role in various industrial applications, particularly in ensuring accurate weight measurement for bulk materials. One of the key benefits of using these scales is their ability to enhance operational efficiency. According to a report by the Material Handling Industry, utilizing advanced weighing solutions like belt counterweight scales can lead to a 15-20% increase in productivity by minimizing material loss and improving inventory management.

In addition to increased efficiency, belt counterweight scales also promote safety and compliance within industrial settings. By providing real-time weight data, these scales help operators prevent overloading which can result in equipment damage or safety hazards. The National Institute for Occupational Safety and Health estimates that using effective weighing systems can reduce workplace accidents related to material handling by up to 30%.

Tip: Regular calibration of your belt counterweight scales is essential for maintaining accuracy. Schedule routine checks to ensure that the scales remain within the manufacturer’s specified tolerances, which will not only enhance precision but also prolong the lifespan of your equipment.

Another benefit worth noting is the versatility of belt counterweight scales. They can be integrated into various systems, making them suitable for different industries, from agriculture to mining. This adaptability allows companies to streamline their processes, ensuring they can respond quickly to changing operational demands while maintaining high standards of accuracy and reliability.

Tip: When selecting a belt counterweight scale, consider the specific material types and environmental conditions in your facility. Choosing a scale that is designed for your particular applications will yield the best performance and longevity.

Belt counterweight scales play a crucial role in enhancing the accuracy of weight measurement in various industrial settings. These scales are designed to weigh materials as they move along conveyor belts, ensuring that the measurement process occurs in real-time. By employing counterweights that adjust dynamically according to the load, these systems minimize errors that can arise from fluctuations in weight distribution or conveyor speed. This precision is vital in industries such as mining, agriculture, and manufacturing, where accurate weight readings are essential for optimizing operations, maintaining regulatory compliance, and ensuring the fair billing of products.

Moreover, the integration of counterweight scales helps in reducing product loss and improving inventory management. By providing accurate data on the amount of material being transported or processed, businesses can make informed decisions about resource allocation and supply chain management. The enhanced accuracy not only supports better operational efficiency but also contributes to cost savings by reducing overloading or underloading situations. As industries increasingly turn to automation and sophisticated measurement technologies, the role of belt counterweight scales becomes even more integral, underscoring their importance in modern industrial applications.

Belt counterweight scales play a pivotal role in enhancing efficiency and productivity within various industrial applications. By accurately measuring the weight of materials on conveyor belts, these scales ensure that operations run smoothly and efficiently. They allow for real-time monitoring of material flow, which helps in maintaining optimal load conditions, reducing wear and tear on equipment, and avoiding costly downtime. Moreover, accurate weight measurements minimize the risk of overloading, which can lead to accidents or damage in industrial settings.

Implementing belt counterweight scales also supports better inventory management and resource allocation. With precise data on material quantities, companies can streamline their supply chain processes, improve forecasting accuracy, and optimize inventory levels. This increased visibility into operations not only boosts productivity but also contributes to overall cost savings. As industries continue to seek ways to improve their workflows, the integration of advanced weighing technologies such as belt counterweight scales becomes increasingly crucial for maintaining a competitive edge.

Belt counterweight scales play a crucial role in industrial applications by ensuring precision in the measurement of bulk materials. One significant advantage of these scales is their cost-effectiveness, which translates into long-term financial benefits for businesses. By accurately measuring the weight of materials conveyed on belts, companies can optimize their operations, reduce waste, and enhance productivity. This precision helps in precise inventory management, enabling businesses to make informed decisions regarding material usage and reducing unnecessary expenditures.

Belt counterweight scales play a crucial role in industrial applications by ensuring precision in the measurement of bulk materials. One significant advantage of these scales is their cost-effectiveness, which translates into long-term financial benefits for businesses. By accurately measuring the weight of materials conveyed on belts, companies can optimize their operations, reduce waste, and enhance productivity. This precision helps in precise inventory management, enabling businesses to make informed decisions regarding material usage and reducing unnecessary expenditures.

Investing in a belt counterweight scale can yield substantial savings over time. For instance, by preventing overloading and ensuring the correct balancing of materials, companies can avoid costly equipment damages and prolong the lifespan of their machinery. Moreover, these scales facilitate compliance with industry regulations, which can lower potential fines or legal issues. Ultimately, the long-term financial benefits of integrating belt counterweight scales into industrial processes far outweigh the initial investment, making them a worthwhile consideration for businesses aiming to improve efficiency and profitability.