Choosing the right Electronic Balance is crucial for industries where precision and accuracy are paramount, such as pharmaceuticals, food production, and laboratory research. According to a report by the International Society for Pharmaceutical Engineering, approximately 40% of quality control failures in pharmaceutical manufacturing can be traced back to improper measurement practices. This highlights the importance of selecting a reliable electronic balance that meets industry standards.

The global laboratory balance market is projected to reach $2.16 billion by 2025, emphasizing the growing demand for high-quality weighing solutions. As businesses strive to enhance efficiency and reduce errors, understanding the key features and specifications of electronic balances becomes essential. In this blog, we will explore five essential tips for selecting the perfect electronic balance that aligns with your specific industry needs, ensuring reliable data and optimal performance.

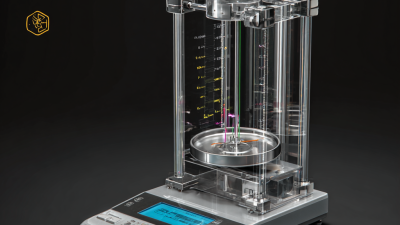

When selecting the perfect electronic balance for laboratory use, understanding balance calibration standards is crucial for ensuring precision. Calibration is the process of adjusting the balance to ensure accurate measurements, and it is essential for industries where even minor discrepancies can lead to significant consequences. Common standards include ISO/IEC standards, which provide guidelines for the calibration process, helping laboratories maintain accuracy and traceability.

Several factors can influence the precision of an electronic balance. Environmental conditions, such as temperature and humidity, can affect the performance of the balance, leading to erroneous readings. Additionally, the quality of the calibration weights used plays a significant role in the calibration process. Utilizing certified weights that meet national or international standards can help ensure that the instrument is finely tuned. Regular maintenance and recalibration schedules are also vital to maintaining the balance's accuracy over time, so users should be proactive in ensuring their equipment meets industry standards. By focusing on these calibration standards and practices, laboratories can enhance the reliability of their measurements.

When selecting an electronic balance, one of the most critical factors to consider is the balance's capacity. This directly correlates with the types of applications and processes within your industry. For instance, laboratories performing analytical weighing typically require balances with high precision and lower capacity, while industrial settings may need balances with greater capacity to handle larger samples. Understanding the specific demands of your work will help you choose a balance that can efficiently meet those requirements, ensuring both accuracy and reliability in your results.

Moreover, it is crucial to match the electronic balance's load capacity with the types of materials being weighed. Using a balance with insufficient capacity can lead to inaccurate measurements and potential damage to the device. Conversely, choosing a balance with excessive capacity for small sample weighing may result in poor sensitivity and resolution. Therefore, thoroughly assessing your weighing needs, considering factors such as the maximum weight of your samples and the frequency of weighing tasks, will guide you in selecting an electronic balance that not only complies with industry standards but also enhances your operational efficiency.

When it comes to selecting the right electronic balance, one of the key factors to consider is its readability, which directly impacts regulatory compliance. Different industries require balances with specific resolutions to ensure accurate measurements. For example, a laboratory performing precise chemical analysis may require a balance with a readability of 0.001 grams, while a manufacturing facility might only need a resolution of 0.01 grams. Before making a decision, assess the regulatory guidelines pertinent to your industry to select a balance that meets these requirements.

Tip 1: Consider the minimum weight requirement. Different applications have varied minimum weight thresholds, and choosing a balance with a suitable resolution is critical for achieving compliance and ensuring accurate results. Always check your industry’s regulations regarding minimum weight to steer your selection.

Tip 2: Familiarize yourself with the concept of readability versus repeatability. Readability refers to the smallest increment the balance can display, while repeatability indicates how consistent the measurements are when the same weight is measured multiple times. Ensure your chosen balance demonstrates excellent performance in both areas to maintain regulatory standards and achieve reliable results.

When selecting an electronic balance, one of the most critical factors to consider is its performance under varying environmental conditions, particularly humidity and temperature. Electronics are inherently sensitive to such variables; therefore, understanding how these factors can impact measurements is essential for achieving reliable results. For instance, high humidity can lead to condensation on sensitive components, causing inaccurate readings or even damage to the device. Similarly, fluctuations in temperature can affect the balance's internal calibration, resulting in drift and compromised precision.

To ensure a high level of accuracy, it's vital to choose a balance that is designed to operate effectively in your specific environment. Look for models equipped with features like draft shields, which can minimize the effects of air currents, and stainless-steel casings resistant to corrosion caused by humidity. Additionally, balances with built-in temperature and humidity sensors can provide real-time feedback, allowing for timely adjustments to maintain optimal performance conditions. Prioritizing these specifications not only enhances measurement accuracy but also extends the lifespan of your equipment, making it a worthwhile investment in any laboratory or industrial setting.

When selecting an electronic balance, it is crucial to compare various features and specifications to ensure reliability and accuracy for your specific industry needs. One essential function to consider is the balance's readability. Models with higher readability, such as 0.1 mg, can provide precise measurements crucial in fields like pharmaceuticals or labs conducting detailed chemical analysis.

Additionally, look for balances equipped with multiple weighing modes, which can enhance versatility, allowing users to switch between different unit measurements effortlessly.

Another vital specification is the maximum capacity of the electronic balance. Depending on your applications, you may require a balance capable of handling larger weights for bulk materials. Ensure the balance also features a robust design that minimizes external influences such as vibrations or air currents — this will help maintain the accuracy of your readings.

Regular calibration capability is another important aspect; choose a model that allows for easy calibration to ensure consistent performance and compliance with industry standards.

Furthermore, user-friendly interfaces and smart connectivity features, like USB or Bluetooth, can streamline your operations. An intuitive display with easy-to-navigate controls will enhance efficiency, while connectivity options can facilitate data transfer and integration with laboratory management systems.

Selecting a balance that incorporates these essential functions will not only optimize your workflow but also enhance the reliability of your measurements.