In the rapidly evolving landscape of industrial automation, staying ahead demands innovative solutions that enhance efficiency and precision. One such groundbreaking technology is Electromagnetic Force Balance, which is significantly transforming automation processes across various sectors. According to a report by McKinsey, implementing advanced automation technologies can boost productivity by up to 20-25%, emphasizing the urgent need for integrating smart solutions.

Electromagnetic Force Balance technology stands out for its ability to provide unparalleled accuracy and reliability in force measurement, thereby increasing the overall productivity of automated systems. Furthermore, the global market for industrial automation is projected to reach $296.70 billion by 2026, driven by interests in advanced technologies, including electromagnetic systems.

As manufacturers seek competitive advantages, understanding the compelling reasons behind the adoption of Electromagnetic Force Balance technology becomes paramount in harnessing its full potential in revolutionizing industrial automation.

Electromagnetic Force Balance (EMFB) technology is taking center stage in the realm of precision data measurement, particularly within industrial automation contexts. By utilizing electromagnetic forces to maintain equilibrium, this innovative technology significantly reduces measurement errors that can arise from environmental factors such as vibrations and temperature fluctuations. According to a recent industry report by McKinsey, implementing EMFB systems can enhance measurement accuracy by up to 95%, leading to improved product consistency and reduced waste.

Utilizing EMFB not only elevates measurement precision but also streamlines the entire production process. For instance, a study by the National Institute of Standards and Technology highlighted that industries employing EMFB technology reported a decrease in calibrating time by approximately 30%. This efficiency translates into cost savings and optimized resource allocation, which are vital for maintaining competitive advantages in today's fast-paced market.

Utilizing EMFB not only elevates measurement precision but also streamlines the entire production process. For instance, a study by the National Institute of Standards and Technology highlighted that industries employing EMFB technology reported a decrease in calibrating time by approximately 30%. This efficiency translates into cost savings and optimized resource allocation, which are vital for maintaining competitive advantages in today's fast-paced market.

Tip: For organizations looking to implement EMFB technology, start by evaluating current measurement processes and identifying areas prone to inaccuracies. Additionally, investing in employee training can maximize the benefits gained from this advanced technology, ensuring optimal performance and reliability in data measurement activities. Another tip is to keep abreast of emerging advancements in EMFB systems, as continuous innovation can lead to even greater efficiencies in industrial automation.

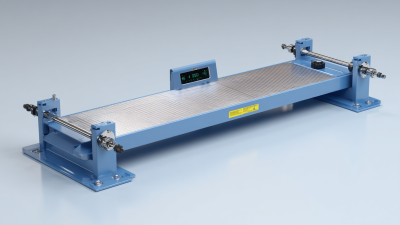

In the realm of modern manufacturing, the integration of Electromagnetic Force Balance (EFB) technology is making waves by enhancing precision and efficiency. EFB systems are employed in various real-world applications, such as the calibration of delicate instruments and the stabilization of machinery. By balancing the electromagnetic forces acting on components, these systems ensure that measurements are accurate and machinery operates smoothly, minimizing downtime and boosting productivity.

Another noteworthy application of EFB technology can be seen in the automation of assembly lines. Through the use of electromagnetic force sensors, manufacturers can monitor the position and orientation of components in real-time, leading to improved alignment and reduced errors during the assembly process. This not only accelerates production times but also significantly increases the consistency and quality of finished products. As industries increasingly adopt this revolutionary technology, the potential for enhanced automation across diverse sectors remains vast and influential.

Electromagnetic Force Balance Technology is setting a new standard in industrial automation, particularly when it comes to enhancing safety protocols. As industries strive for higher efficiency and reliability, this technology offers a groundbreaking approach by providing real-time feedback on system performance. By maintaining balance within machinery, it can significantly reduce the risk of mechanical failure, thereby safeguarding both equipment and personnel in high-stakes environments.

Moreover, the integration of electromagnetic force balance mechanisms leads to more precise control in automated systems. This precision minimizes the chances of accidents caused by unexpected equipment malfunctions. With the ability to detect anomalies and respond promptly, facilities can ensure a safer workplace. This not only protects workers but also reduces potential downtime, ultimately contributing to the overall sustainability of industrial operations. In the landscape of automation, adopting such advanced safety measures positions companies at the forefront of innovation and responsibility.

Electromagnetic Force Balance Technology is at the forefront of modern industrial automation, primarily due to its remarkable ability to optimize energy efficiency. By using electromagnetic principles to balance forces within machinery, this technology minimizes wasted energy, leading to more streamlined operations. As machines run with reduced friction and optimized motion, manufacturers can experience significant cost savings and enhanced performance.

Tips for implementing electromagnetic force balance in your operations include regularly monitoring your machinery's energy consumption. This will help identify areas where excess energy is being expended, allowing for targeted adjustments. Furthermore, investing in training for your staff on the fundamentals of electromagnetic systems can empower them to operate and maintain equipment more effectively, ensuring the full benefits of reduced energy usage.

Another key tip is to integrate real-time data analytics into your automation system. By leveraging data, companies can gain insights into operational efficiency and energy consumption patterns. These insights enable informed decision-making that ultimately leads to smarter energy management and improved productivity across the board.

Electromagnetic Force Balance (EFB) technology marks a significant shift in the realm of industrial automation, providing advantages over traditional methods. Traditional automation relies heavily on mechanical systems that can wear out over time, leading to decreased efficiency and increased maintenance costs. These systems often struggle with precision and adaptability, especially in rapidly changing production environments. In contrast, EFB technology employs electromagnetic principles to provide a robust and flexible solution, ensuring high accuracy and reliability while minimizing mechanical degradation.

Moreover, the responsiveness of EFB systems far exceeds that of traditional automation. With instant real-time adjustments to load changes and external disturbances, these systems enhance operational efficiency significantly. Unlike their mechanical counterparts, which may require time to recalibrate or adjust, EFB systems can react within milliseconds, thus improving overall production throughput. Additionally, the integration of EFB technology in automation systems enables industries to move towards smarter factories, leveraging data analytics and IoT capabilities for enhanced operational insights, showcasing a step change in how manufacturing processes are optimized.

| Aspect | Electromagnetic Force Balance Technology | Traditional Automation Methods |

|---|---|---|

| Energy Efficiency | Significantly reduces energy consumption by 30-50% | Typical energy savings of 10-20% |

| Precision | Offers positioning accuracy within ±0.1 mm | Accurate to ±0.5 mm, depending on equipment |

| Response Time | Immediate response time of less than 10 ms | Response time between 50 ms to 200 ms |

| Maintenance | Minimal maintenance required, reducing downtime | Regular maintenance needed every few months |

| Flexibility | Easily adjustable for various applications | Less adaptable, often limited to specific tasks |