The Rotary Collecting Table Machine is essential in modern manufacturing. This tool improves efficiency by streamlining the collection process. When used correctly, it can significantly boost production rates.

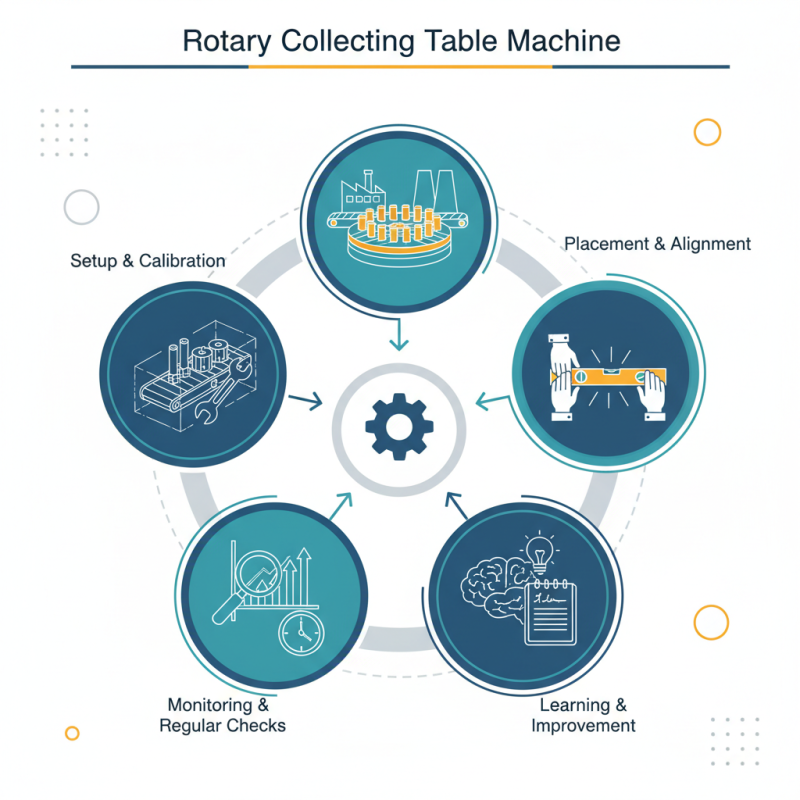

Understanding its setup is crucial. Operators must familiarize themselves with the machine's various components. Placement and calibration play key roles in achieving optimal performance. A misaligned table can lead to wasted resources and time.

It is important to monitor operations closely. Regular checks help identify potential issues early. Operators may learn from mistakes made during initial use. Reflection on these experiences can lead to improved performance and productivity over time. Emphasizing these details ensures that the Rotary Collecting Table Machine is used to its full potential.

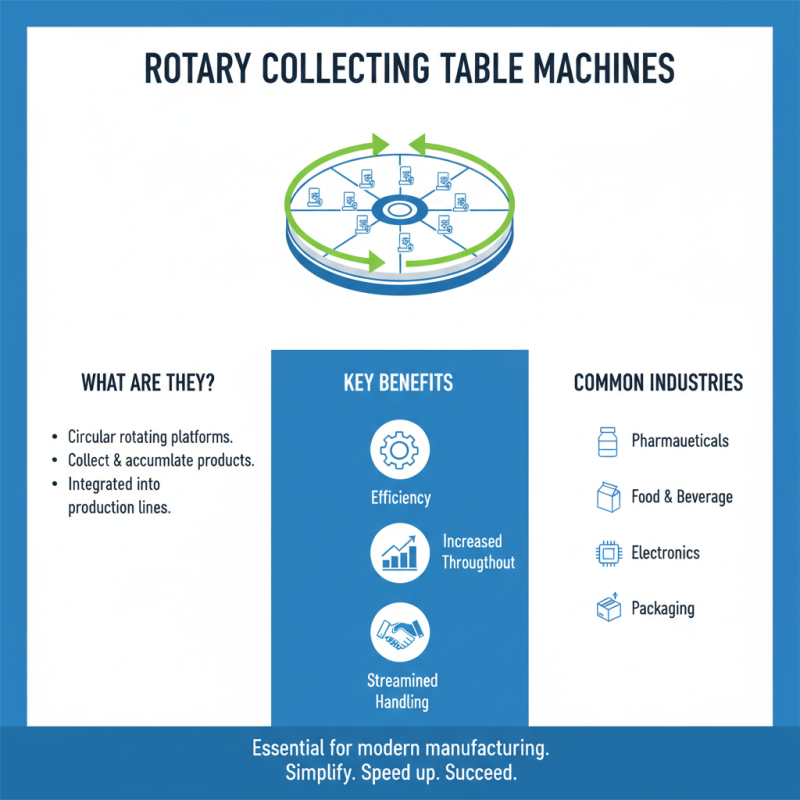

Rotary collecting table machines are vital in various industries. They facilitate the efficient handling and assembly of products in a streamlined manner. Understanding their basics can greatly enhance their effectiveness in operations.

These machines use rotating tables to collect components. They are designed to gather items from different sources and direct them to designated areas. Users often struggle with adjusting the speed. It’s crucial to find a balance that suits your workflow. If the speed is too fast, parts can fall off. Too slow, and productivity suffers.

Regular maintenance is key. Dust and debris can accumulate and affect performance. A clean machine runs smoother and lasts longer. Operators should regularly check moving parts. Failure to maintain these components can lead to breakdowns. Reflecting on these factors will improve the overall efficiency of a rotary collecting table machine.

Rotary collecting table machines play a crucial role in various industrial processes. These machines consist of key components like the rotary table, control panel, and safety features. The rotary table rotates to facilitate the smooth transfer of materials. This allows for

efficient handling of products in manufacturing and assembly lines.

The control panel is vital. It manages the speed and direction of the table’s rotation. Operators must understand how to adjust these settings for optimal performance. Sometimes, there can be a learning curve. Mistakes, such as setting incorrect speeds, can lead to production hiccups. These errors require operators to rethink their approach.

Safety mechanisms are equally important. They ensure that the machine operates without risk to personnel. Regular maintenance checks are necessary to keep these features functional. Neglecting them could lead to accidents. Operators should regularly review their machinery for any signs of wear or malfunction. This proactive approach can help avoid larger issues down the line.

Setting up a rotary collecting table machine requires careful attention to detail. Begin by choosing the right location. The machine needs ample space for operation and maintenance. Ensure that the surface is level. According to industry reports, a stable foundation minimizes vibrations. This can improve accuracy by nearly 30%.

Next, properly align and integrate the machine with other equipment. Follow the manufacturer's guidelines for connections and adjustments. A misalignment of just a few millimeters can lead to significant inefficiencies. This often results in increased wear and tear. Regular calibration checks are essential. Many operators forget this step, leading to production delays.

Once everything is set, conduct trial runs. Monitor the output quality closely. Data indicates that nearly 20% of new setups require immediate adjustments after initial use. Document any issues you face. This reflection helps in refining processes over time. Regular assessments will lead to better efficiency. Aim for consistent performance to prevent long-term complications.

Operating a rotary collecting table machine requires attention and care. Proper setup is essential for optimal performance. Make sure the machine is level. Uneven surfaces can lead to operational issues. Regularly check the alignment of the table to prevent inconsistent material flow. Inadequate alignment may result in product loss and inefficient processes.

Maintenance plays a crucial role in extending the life of the machine. Regularly clean the components to avoid debris buildup. Dust and dirt can affect machinery efficiency. Lubrication is equally important. Ensure that all moving parts are adequately lubricated on a regular basis. Neglecting this can lead to wear and tear.

Operators should also undergo training to understand the machine’s functions. Misunderstanding controls can lead to mistakes, impacting productivity. Pay attention to warning signals or unusual noises during operation. These signs could indicate potential problems. Take the time to reflect on operational practices. Improving small details can make a significant difference.

| Aspect | Best Practices | Maintenance Tips | Common Issues |

|---|---|---|---|

| Setup | Ensure level and stable placement of the machine. | Regularly check mechanical components for wear. | Misalignment during operation. |

| Operation | Train operators on machine functions and safety. | Clean and lubricate moving parts monthly. | Inconsistent speed or rotation issues. |

| Adjustment | Regularly calibrate settings according to product specifications. | Replace worn gears promptly. | Product misalignment or jamming. |

| Safety | Utilize safety guards and emergency stop features. | Conduct safety audits quarterly. | Operator injuries or machine accidents. |

| Troubleshooting | Follow the manufacturer's guidelines for issue resolution. | Document repair histories to identify recurring problems. | Frequent breakdowns or error messages. |

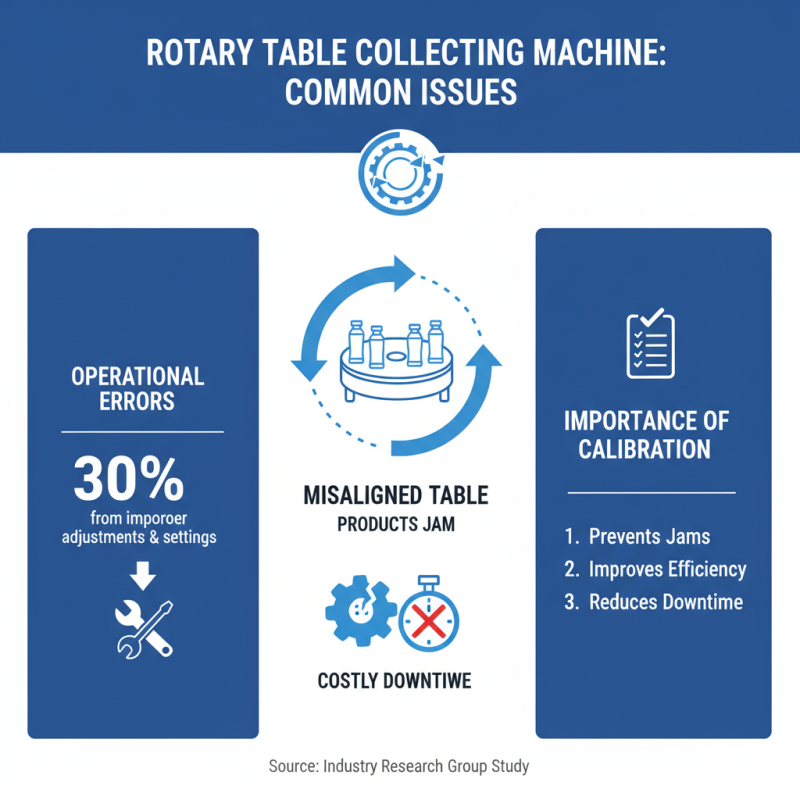

When using a rotary collecting table machine, common issues may arise that require attention. A study from the Industry Research Group indicates that nearly 30% of operational errors stem from improper adjustments and settings. Operators often overlook the importance of calibrated settings, leading to inefficient performance. For instance, a misaligned table can cause products to jam, leading to costly downtime.

Routine maintenance is crucial in ensuring effective performance. Neglecting regular checks can result in wear and tear, which affects production rates. Data from Machinery Insights shows that machines maintained bi-weekly report 15% higher efficiency compared to those serviced less frequently. Identify potential trouble spots. Look for unusual sounds or irregular movements. These can signal underlying problems that require immediate action.

Lastly, training staff on troubleshooting is essential. Many operators may not know how to reset the machine after a minor error. Reports highlight that companies with comprehensive training programs see a 20% reduction in machine-related incidents. Regular training sessions can equip your team to quickly resolve issues, ultimately saving time and resources.