The poultry processing industry has experienced significant advancements over the last decade, with technology playing a crucial role in enhancing operational efficiency and product quality. According to a recent report by the International Poultry Council, the global market for chicken sorting machines is projected to grow at a CAGR of 5.6% through 2025, driven by increasing demand for food safety and quality assurance. As businesses scale, investing in the right Chicken Sorting Machine becomes instrumental not just for compliance but also for maintaining competitiveness in a rapidly evolving market.

Choosing an optimal chicken sorting machine is pivotal, given the diverse operating conditions and varying business needs. Factors such as speed, accuracy, and adaptability to different chicken sizes are crucial in determining the machine’s effectiveness. The right equipment can streamline operations, reduce labor costs, and enhance yield quality, all while ensuring the safety and compliance standards necessary in today’s food production landscape. This guide will provide you with the top 10 tips to consider when selecting the best chicken sorting machine, equipping you with the insights needed to make an informed investment that aligns with your business goals.

When selecting a chicken sorting machine for your business, it is crucial to thoroughly understand your specific operational needs. Start by evaluating the volume of chickens you process daily, as this will influence the machine's capacity. Additionally, consider the different sizes and weights of the chickens you handle, as versatility in sorting options can enhance efficiency. Knowing the required output and speeds will also help you narrow down your options.

One essential tip is to prioritize durability and maintenance requirements when choosing a machine. A robust design that withstands heavy usage will save time and costs associated with repairs. Furthermore, assess the ease of cleaning and maintenance; machines with accessible parts can significantly reduce downtime.

Lastly, think about the technological features that align with your business model. Some machines come equipped with advanced sorting algorithms and automated systems that increase accuracy and speed. These features may represent a higher upfront cost but can lead to improved productivity and profitability in the long run. By aligning the sorting machine's capabilities with your business needs, you set a strong foundation for success in your chicken processing operations.

This bar chart illustrates the importance rating for various factors to consider when selecting a chicken sorting machine for your business. Each factor is rated on a scale from 1 to 10, highlighting how critical they are in the decision-making process.

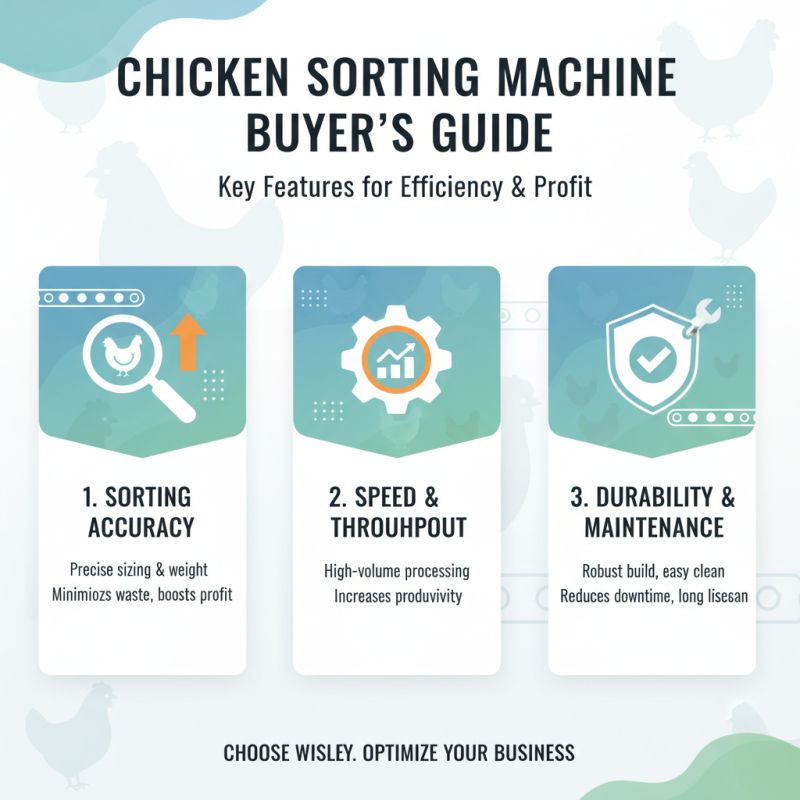

When selecting the right chicken sorting machine for your business, it is crucial to focus on several key features that enhance performance and efficiency. First and foremost, consider the machine's sorting accuracy. A high-quality sorting machine should have advanced technology that can precisely differentiate between various sizes and weights of chicken. This precision not only improves the consistency of your product but also minimizes waste, ensuring you maximize profitability.

Another important feature is the machine's throughput capacity. Depending on the scale of your operations, you need a model that can handle your production volume without bottlenecks. Look for machines that offer adjustable speeds and can adapt to varying production demands. Additionally, ease of maintenance is vital; machines with accessible parts and straightforward cleaning procedures will reduce downtime and enhance productivity. Lastly, consider the machine’s adaptability to various product types, as this flexibility allows your business to adjust to changing market needs without incurring substantial costs.

When it comes to selecting a chicken sorting machine, understanding the various sorting technologies available is crucial. Different types of technologies cater to distinct sorting needs, ensuring that your operation runs efficiently and meets quality standards. For instance, optical sorting machines use advanced imaging and artificial intelligence to identify and classify chickens based on size, weight, and even color. This technology provides high accuracy and can sort large volumes quickly, making it ideal for businesses that demand speed and precision.

Another common sorting technology is the mechanical sorter, which typically relies on a combination of conveyor belts and size-specific openings to separate chickens. These machines are not only cost-effective but also relatively easy to maintain, making them a popular choice among smaller operations. However, they may lack the sophisticated features of their optical counterparts, potentially affecting sorting accuracy for certain criteria. Ultimately, understanding these technologies and their respective advantages will empower businesses to make informed decisions that align with their operational goals.

When selecting a chicken sorting machine for your business, evaluating the reliability and maintenance of the equipment is crucial. According to industry reports, downtime due to equipment failure can result in substantial financial losses, estimated to be around $100,000 annually for mid-sized poultry operations. Therefore, understanding the machinery's build quality and reliability history can provide insights into its long-term performance. It’s important to look for machines made from durable materials that can withstand frequent use and harsh working conditions. Operational reliability is often indicated by the manufacturer's warranty and customer reviews, which can highlight long-term dependability.

Maintenance practices are another essential consideration. A well-maintained sorting machine can significantly enhance productivity and prolong its lifespan. Research indicates that regular maintenance can reduce operational costs by up to 20%, as it minimizes unplanned downtime and extends machine longevity. It is advisable to choose equipment that offers easy access to critical components for routine checks and repairs. Additionally, some suppliers may provide comprehensive maintenance plans, which can alleviate some of the burdens from your operational staff. Investing in machines that offer user-friendly maintenance features not only improves efficiency but also contributes to a safer working environment by reducing the risk of accidents during repairs.

| Tip No. | Tip Description | Key Considerations | Maintenance Requirements |

|---|---|---|---|

| 1 | Assess Sorting Capacity | Consider volume of chickens processed | Regular cleaning and calibration |

| 2 | Evaluate Sorting Accuracy | Minimum acceptable error rates | Frequent performance checks |

| 3 | Consider Machine Durability | Materials used in construction | Inspect for wear and tear |

| 4 | Check for Automation Features | Ease of operation with automation | Software updates and training |

| 5 | Review Energy Efficiency | Energy consumption metrics | Systematic energy audits |

| 6 | Assess Size and Footprint | Space available in your facility | Mobility and adaptability |

| 7 | Consider User-Friendliness | Ease of operation for staff | Operator training and manuals |

| 8 | Investigate Customer Support | Availability of support services | Response time for maintenance requests |

| 9 | Explore Cost of Ownership | Initial purchase and operational costs | Budgeting for repairs and parts |

| 10 | Read Reviews and Feedback | Input from other businesses | Learn from user experiences |

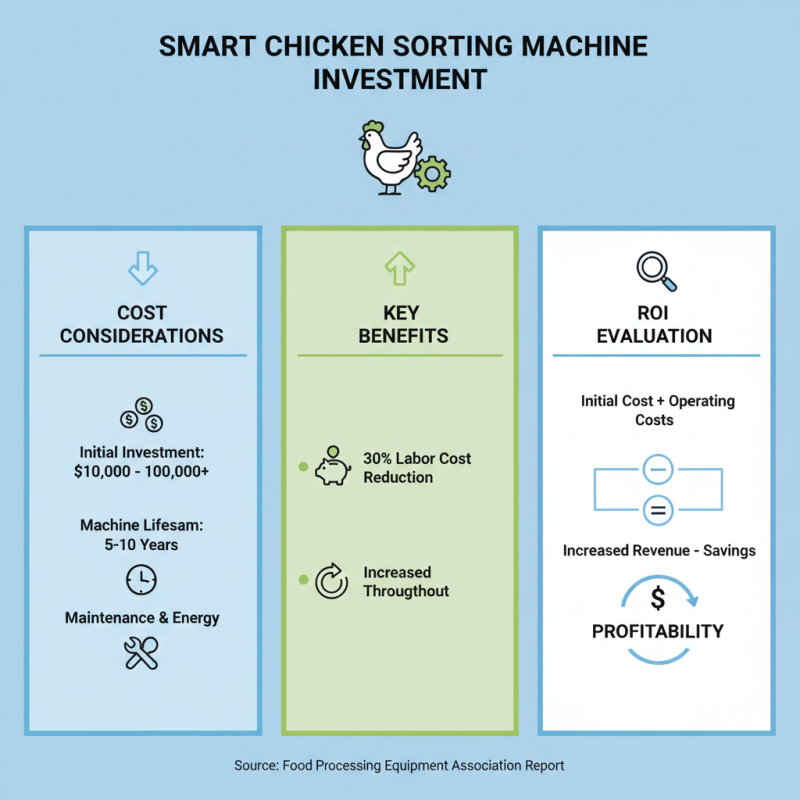

When selecting a chicken sorting machine, budgeting and cost considerations play a critical role in shaping your business’s operational efficiency and profitability. According to a recent report by the Food Processing Equipment Association, investing in quality sorting machinery can lead to a 30% reduction in labor costs and a significant increase in throughput. However, the initial investment can range widely, with basic models starting around $10,000 and more advanced systems exceeding $100,000. It is crucial to evaluate the return on investment and consider factors such as machine lifespan, maintenance costs, and energy consumption.

To effectively allocate your budget, it is important to assess the total cost of ownership (TCO) for chicken sorting equipment. TCO includes not only the upfront purchase price but also operational costs over the machine's lifespan. Recent market analysis suggests that the average lifespan of a sorting machine ranges from 10 to 15 years, and within that period, businesses may spend up to 20% of the acquisition cost on maintenance and repairs. This statistic underscores the importance of not just the purchase price but the ongoing costs associated with the equipment. Furthermore, advancements in technology may offer newer machines that provide higher efficiency, which can lower overall costs in the long run through better energy usage and less downtime. Therefore, a comprehensive approach to budgeting can ensure a more informed decision-making process when selecting the best sorting machine for your operational needs.