Choosing the right Fruit Sorting Machine is crucial for any fruit processing operation. A good machine improves efficiency and quality. It helps identify ripe fruits and separates damaged ones. The right machine can save time and labor costs significantly.

When evaluating your options, consider factors like capacity and technology. Some machines use advanced sensors to detect size and color. Others may focus on simplicity and ease of use. Each has its benefits and drawbacks.

It's important to reflect on your specific needs. Do you process various fruit types? Or are you focused on one? This choice will influence your best fit. Investing in a quality Fruit Sorting Machine can lead to better market standards. However, the wrong decision may waste resources. Careful consideration will pay off in the long run.

When selecting a fruit sorting machine, it's essential to understand the different types available.

Optical sorters use cameras and sensors to identify imperfections in fruit. This technology can enhance sorting efficiency by up to 95%. It ensures each piece of fruit meets quality standards before reaching consumers.

Mechanical sorters, on the other hand, rely on physical attributes to separate fruits. They can handle large volumes but may struggle with delicate fruits. For example, the average sorting speed for mechanical systems is around 5 tons per hour. However, they often miss subtle defects that optical systems easily catch.

In recent studies, many farms report a 30% increase in profit when investing in advanced sorting technology. Yet, capital costs can be prohibitive. Farmers must balance the initial investment with potential long-term gains. Choosing the right machine can be challenging. It's crucial to weigh these factors carefully to achieve optimal results.

Choosing the right fruit sorting machine starts with understanding your production needs. Consider your current output. Are you sorting tens or hundreds of fruits daily? Each scenario requires different machinery. If you have high volumes, invest in a machine with faster throughput. Slower machines can hinder production and lead to bottlenecks.

Capacity requirements are also essential. Think about the size of your fruits. Some machines handle larger apples but struggle with petite berries. If you deal with various sizes, flexibility is crucial. Be mindful of your space as well. A larger machine might seem efficient, but it also needs adequate room for operation.

Reflect on your long-term goals. Will your production scale up? If so, consider machines that can expand with your needs. It’s important not to rush this decision. Evaluate your choices carefully. Sometimes, the perfect machine might not be the most obvious one. Take the time to assess and ensure the machine aligns with your expectations.

| Machine Type | Sorting Capacity (kg/h) | Features | Suitable Fruits | Price Range (USD) |

|---|---|---|---|---|

| Optical Sorting Machine | 2000 | High precision sorting, color detection | Apples, Tomatoes, Cherries | $15,000 - $50,000 |

| Weight Sorting Machine | 1500 | Weight-based sorting | Oranges, Grapes | $10,000 - $30,000 |

| Manual Sorting Table | N/A | Cost-effective, simple setup | All fruits | $1,000 - $5,000 |

| Vibration Sorting Machine | 1000 | Gentle handling, adjustable speed | Berries, Peppers | $8,000 - $20,000 |

| Laser Sorting Machine | 2500 | Advanced laser detection | Peaches, Plums | $20,000 - $70,000 |

When selecting a fruit sorting machine, understanding key features is critical. A reliable sorting system should offer advanced technology for precision and efficiency. According to industry reports, machines with high-speed cameras can identify color variations in fruits accurately. This ensures only the best quality fruits reach consumers.

Another essential feature is the capacity of the machine. Sorting machines can process anywhere from 1 ton to over 10 tons per hour. Depending on your production scale, it’s important to choose a machine that meets your needs. Many operations underestimate the power of scalability, leading to bottlenecks in production.

Maintenance can be a concern as well. Users often overlook ease of cleaning and servicing. Regular maintenance influences the machine's longevity and efficiency. Reports indicate that neglected machines can lead to a productivity drop of up to 20%. A good machine should not only sort fruit well but also be easy to maintain. Choosing wisely now can prevent costly issues later.

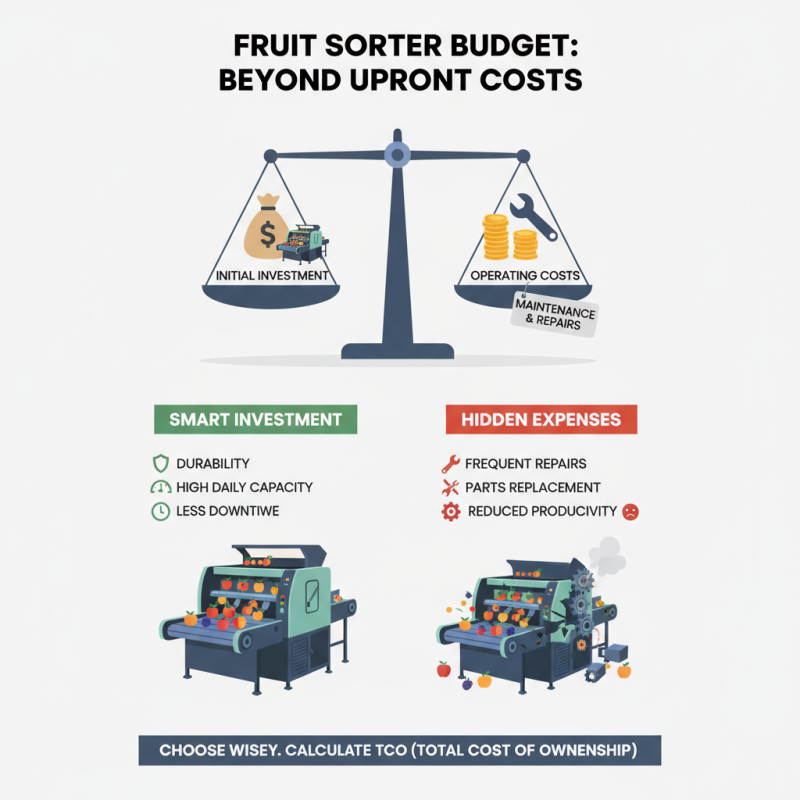

When evaluating the budget for a fruit sorting machine, it's crucial to consider not just the upfront costs. Maintenance costs can add up over time. Some machines may require more frequent repairs, impacting your overall expenditure. Assess how many fruits you need to sort daily. If the demand is high, investing in a durable machine might be wise, even if it costs more initially.

Cost-effectiveness also involves energy consumption. An efficient machine may have a higher purchase price but save you money in the long run. Check the specifications on energy usage. A machine that sorts fruit quickly can increase productivity too. But remember, faster machines can be pricier. Think about your operation's workflow and how a new machine fits into it.

It’s also helpful to analyze potential productivity boosts. A more expensive machine may sort fruits faster, resulting in less labor cost. However, reflect on whether this speed aligns with your business needs. Inconsistent sorting quality may also create waste. Balancing quality and cost is essential. Remember that not every expensive machine guarantees the best results.

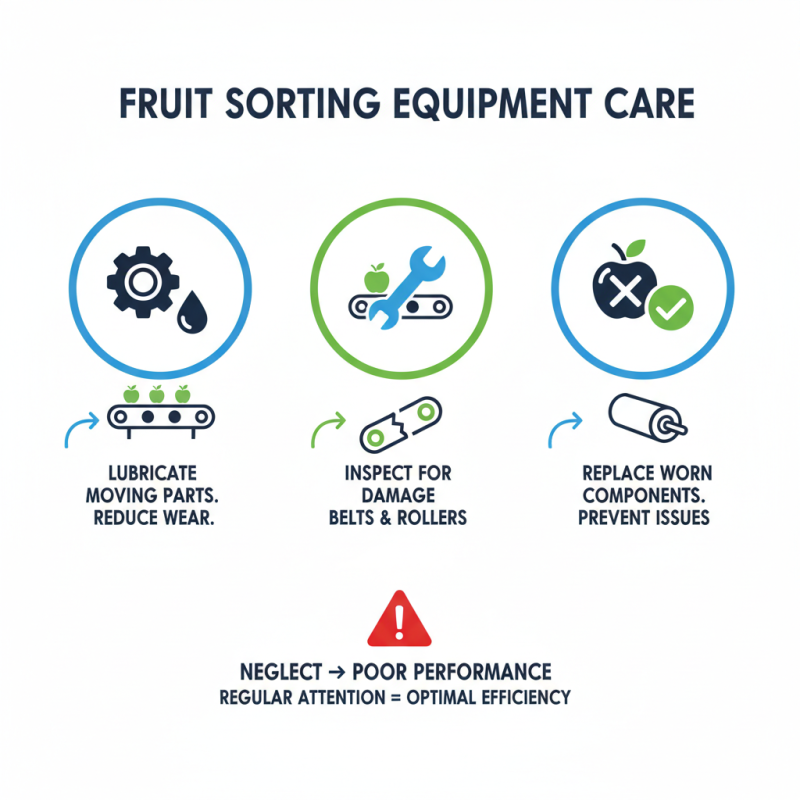

Maintaining fruit sorting equipment requires regular attention. Neglect can lead to poor performance. Ensure all moving parts are lubricated. This can reduce wear and tear. Check belts and rollers for any signs of damage. Replace any worn components immediately to prevent further issues.

Regular cleaning is crucial for optimal performance. Dust and fruit residue can accumulate quickly. Schedule daily cleanings after production runs. Use appropriate cleaning agents that won't harm the equipment. Consider the condition of the sensors and cameras too. They need to be clear for accurate sorting.

Support for your equipment should not be overlooked. Have a technician regularly inspect the machine. They can spot potential problems early. Create a maintenance log to track schedules and repairs. This helps in identifying recurring issues. An organized approach keeps your equipment running efficiently. Reflection on the machine's performance can reveal areas for improvement. Adjusting practices based on ongoing observations leads to better outcomes.