In today's fast-paced packaging industry, precision and efficiency are paramount. The adoption of technologies such as Checkweigher Online has become increasingly essential for manufacturers looking to enhance their processes. According to a recent market report by ResearchAndMarkets, the global checkweighers market is projected to reach $646 million by 2026, underscoring the importance of accurate weight verification in packaging operations. The integration of Checkweigher Online solutions not only helps reduce product giveaway but also minimizes the risk of packaging errors, leading to significant cost savings and improved product quality.

Industry expert Dr. Michael Larson, a leading analyst at Packaging Insights, emphasizes the transformative impact of these technologies. He states, "With Checkweigher Online systems, manufacturers can streamline their packaging processes, ensuring that every package is compliant with weight standards while maximizing operational efficiency." As more companies recognize the value of automated checkweighing systems, understanding their functionality and benefits becomes crucial. By implementing Checkweigher Online strategies, businesses can navigate the complex landscape of packaging with greater accuracy, ensuring that they meet both regulatory demands and customer expectations alike.

A checkweigher is an essential instrument used in the packaging industry to ensure that products meet specified weight specifications. Its primary role is to automate the weight verification process, helping manufacturers maintain compliance with legal regulations and quality standards. In various sectors, including food and beverage, pharmaceuticals, and consumer goods, accurate weight measurement is critical to prevent costly penalties due to underfilled products, which can amount to significant losses—reports estimate that packaging inaccuracies can lead to more than $10 billion in revenue loss annually.

The implementation of checkweighers in the packaging process enables businesses to enhance efficiency while ensuring product integrity. By incorporating advanced technologies such as dynamic weighing systems and software integrations, companies can achieve high-speed throughput without sacrificing accuracy. According to industry studies, manufacturers that leverage automated checkweighing systems have reported improvements in productivity by up to 25%, along with a notable reduction in labor costs associated with manual inspections. Furthermore, the data collected from checkweighers also provides valuable insights into production trends, allowing teams to make informed decisions that streamline operations and minimize waste.

Checkweighers are essential tools in the packaging industry, designed to ensure that products are accurately weighed before they are packaged and shipped. There are various types of checkweighers available, each equipped with unique features tailored to specific operational needs. The most common types include static checkweighers, dynamic checkweighers, and multirange checkweighers. Static checkweighers are typically used for products that are already in a fixed position, allowing for precise weight measurement without the need for movement during the weighing process.

Dynamic checkweighers, on the other hand, are designed for high-speed operations, automatically weighing products as they pass through the system on conveyors. This type is ideal for manufacturers who need to maintain efficiency while ensuring weight accuracy. Multirange checkweighers provide versatility by allowing operators to weigh items of varying weights within a single unit, thus accommodating different product lines without extensive recalibration. Each of these options can significantly enhance accuracy and productivity within a packaging process, reducing the risk of underweight or overweight shipments and helping companies comply with regulations.

| Type of Checkweigher | Description | Accuracy | Speed (items/min) | Use Case |

|---|---|---|---|---|

| Dynamic Checkweigher | Measures the weight of products in motion on a conveyor. | ±0.5g | 120 | Food packaging, pharmaceuticals |

| Static Checkweigher | Measures weight when the product is stationary. | ±1g | 30 | Quality control checks |

| Multi-lane Checkweigher | Used for weighing multiple products simultaneously in parallel lanes. | ±0.2g | 150 | High-speed production lines |

| Checkweigher with Metal Detector | Combines weight measurement with a metal detection system. | ±0.3g | 100 | Food safety compliance |

Checkweighers play a crucial role in enhancing the accuracy and efficiency of packaging processes across various industries. By ensuring that products meet specific weight standards before they reach consumers, checkweighers help manufacturers avoid costly penalties due to underweight packages. According to a report by PMMI, the Association for Packaging and Processing Technologies, implementing checkweighers can reduce product giveaways by up to 1% to 3%. This not only helps companies maintain compliance with regulatory standards but also leads to significant cost savings over time.

In addition to minimizing product loss, checkweighers contribute to overall operational efficiency by streamlining the packaging line. A study by Smithers Pira indicates that automated checkweighers can improve packaging speed by as much as 30% when integrated effectively into production workflows. The influx of real-time data allows manufacturers to make informed adjustments on the fly, leading to consistent product quality and better resource management. As industries continue to prioritize precision and efficiency, the adoption of checkweighers is becoming an essential element of successful packaging strategies.

Integrating checkweighers into existing packaging lines offers a significant opportunity for manufacturers seeking to enhance efficiency and accuracy. By seamlessly incorporating these devices, businesses can monitor the weight of products in real time, ensuring that each package meets the specified weight requirements without manual inspections. This automation not only speeds up the packaging process but also reduces the likelihood of human error, leading to improved product consistency and compliance with regulatory standards.

Tips for successful integration include assessing the current packaging workflow to identify the best placement for the checkweigher. Ensure that the checkweigher supports the speed and volume of your production line, as well as the types of products being packaged. Equipping staff with adequate training on operating and maintaining the equipment can also maximize benefits and minimize downtime.

Additionally, consider implementing a feedback loop by utilizing data gathered from the checkweigher to continuously refine packaging processes. Analyzing trends in weight discrepancies can provide insights into potential issues with raw materials or equipment, allowing you to take proactive measures to enhance quality control. By leveraging the capabilities of checkweighers, businesses can not only streamline operations but also bolster customer satisfaction through consistent product quality.

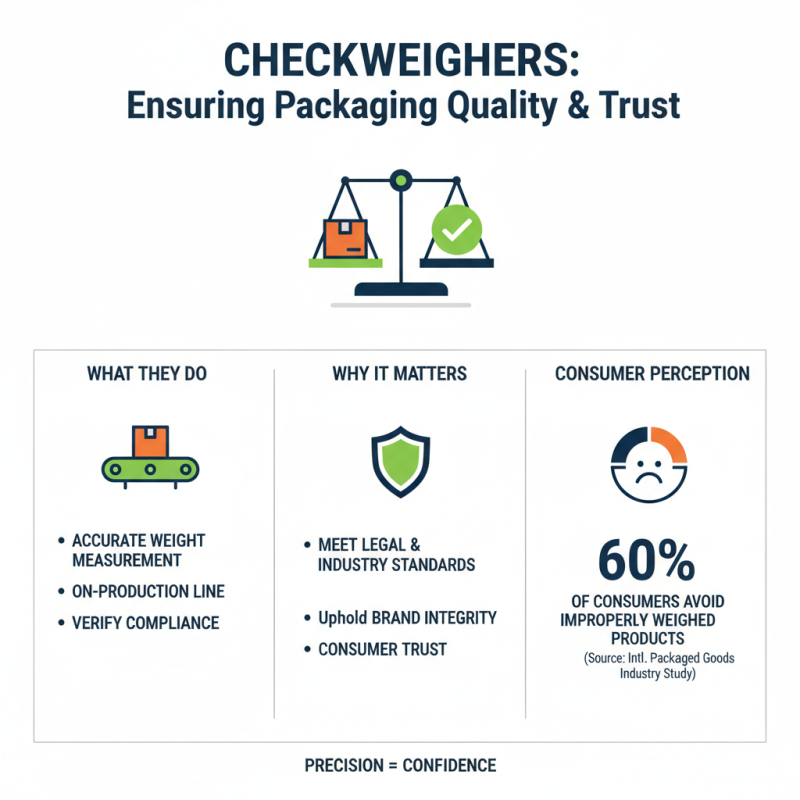

Checkweighers play a vital role in ensuring quality control standards within the packaging process. By accurately measuring the weight of products on the production line, checkweighers help manufacturers verify compliance with legal and industry standards. According to a study by the International Packaged Goods Industry, nearly 60% of consumers say they would not purchase a product if it were improperly weighted. This statistic underscores the importance of maintaining precise measurements to uphold the brand's integrity and consumer trust.

Implementing checkweighers can significantly reduce product giveaway and minimize the risk of non-compliance penalties. A report from the Packaging Machinery Manufacturers Institute highlights that using automated checkweighers can reduce material waste by up to 10%, directly impacting the bottom line. Furthermore, consistent weight checks help companies avoid costly product recalls related to weight discrepancies. As the industry shifts toward more automated solutions, the integration of checkweighers into the packaging process not only strengthens quality control measures but also enhances operational efficiency, ultimately leading to increased profitability for manufacturers.