In industrial applications, precision and efficiency are paramount, especially when it comes to material handling systems. A crucial component in ensuring accurate weight measurement is the Belt Counterweight Scale, which is designed to provide real-time data on the load being transported. According to a report by the International Society of Automation, incorrect weight readings can lead to operational inefficiencies, costing industries an estimated $2.5 billion annually due to errors in inventory management and process control. With advancements in technology, modern Belt Counterweight Scales now incorporate state-of-the-art sensors and software that enhance their accuracy and reliability. This ultimate guide delves into the functionality, benefits, and best practices associated with the use of Belt Counterweight Scales in various industrial environments, offering insights that can help businesses optimize their operations and reduce costs.

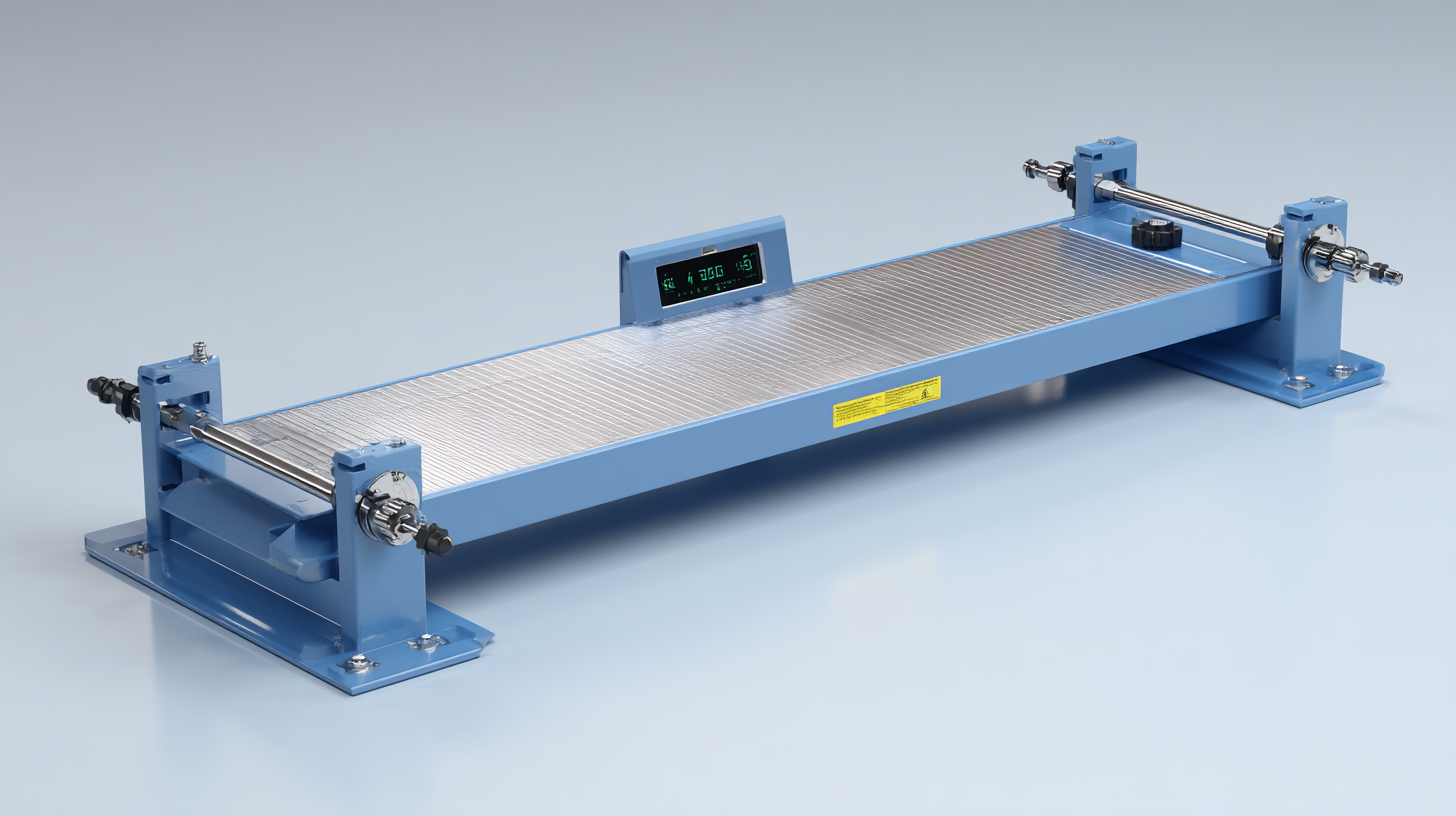

Belt counterweight scales play a crucial role in various industrial applications, providing precise measurement and consistent calibration essential for operational efficiency. One of the key features of these scales is their robust design, which ensures durability and reliability, even in harsh environments. Made from high-quality materials, they can withstand intense vibrations and heavy loads, making them ideal for industries such as mining, construction, and manufacturing.

Belt counterweight scales play a crucial role in various industrial applications, providing precise measurement and consistent calibration essential for operational efficiency. One of the key features of these scales is their robust design, which ensures durability and reliability, even in harsh environments. Made from high-quality materials, they can withstand intense vibrations and heavy loads, making them ideal for industries such as mining, construction, and manufacturing.

Another significant aspect of belt counterweight scales is their advanced technology, which includes automatic calibration and real-time data processing. This feature allows operators to obtain accurate weight measurements swiftly, reducing manual input errors and saving valuable time. Additionally, many modern belt counterweight scales offer connectivity options, enabling seamless integration with existing systems for analytics and monitoring. The adaptability of these scales to meet specific industry requirements ensures that businesses can optimize their processes, improve safety standards, and enhance productivity across the board.

In industrial applications, the belt counterweight scale plays a crucial role in maintaining operational efficiency and accuracy. There are various types of belt counterweight scales available, each designed to meet specific needs within different industries. For instance, some scales are designed for high-capacity environments, allowing for the seamless weighing of large quantities of materials, while others focus on precision, offering advanced measurement capabilities for smaller loads.

The specifications of these scales can vary significantly, with features such as automated calibration, digital readouts, and robust construction materials to withstand harsh industrial conditions. Some models incorporate advanced technology, such as wireless connectivity and integration with management software, to provide real-time data monitoring and reporting capabilities. Understanding the unique functionalities and specifications of each product type can aid businesses in selecting the right scale to enhance productivity and ensure compliance with industry standards.

| Product Type | Maximum Capacity | Accuracy | Operational Environment | Unique Features |

|---|---|---|---|---|

| Digital Belt Counterweight Scale | 3000 kg | ±1 kg | Indoor and outdoor | LED Display, Wireless Connectivity |

| Mechanical Belt Scale | 2000 kg | ±2 kg | Indoor only | Durable design, Low maintenance |

| Portable Belt Scale | 1000 kg | ±0.5 kg | Flexible use | Compact size, Easy transport |

| Heavy-Duty Belt Scale | 5000 kg | ±1.5 kg | Harsh environments | Robust construction, Anti-corrosive |

When selecting the right belt counterweight scale for your industry, it’s essential to consider several factors that align with your operational needs. The scale's accuracy is paramount; whether it’s for monitoring materials in manufacturing or logistics, precision can significantly affect productivity and cost management. Additionally, the durability of the system in harsh environments cannot be overstated. Industries like mining or construction frequently encounter extreme conditions, making resilience a crucial feature in ensuring consistent performance over time.

Recent innovations in this field highlight the importance of real-time monitoring technologies. For instance, a new patent for a belt tear detection device enhances operational safety by allowing for immediate assessment of belt integrity. Such advancements not only improve efficiency but also bolster safety protocols in industrial settings. Therefore, while selecting a belt counterweight scale, it’s beneficial to watch for features that integrate modern monitoring solutions, as these can provide significant advantages in both reliability and operational oversight.

Belt counterweight scales play a crucial role in enhancing efficiency in material handling processes across various industries. These scales are designed to accurately measure the weight of materials being transported on conveyor belts, ensuring that operators can monitor and control the flow of materials with precision. By providing real-time data on weights, these systems help in making informed decisions, optimizing operations, and minimizing waste. This accuracy is especially beneficial in industries where precise weight measurement is essential for compliance and inventory management.

One of the primary advantages of using belt counterweight scales is the significant reduction in operational costs. By accurately measuring materials, companies can prevent overloading, which not only protects the machinery but also reduces wear and tear, extending equipment life. Furthermore, the integration of these scales into existing conveyor systems streamlines workflows, allowing for faster loading and unloading processes. As a result, businesses can achieve higher productivity levels while maintaining safety standards, leading to an overall improvement in operational efficiency. Investing in belt counterweight scales is, therefore, a strategic move for any industry aiming to enhance their material handling capabilities.

Belt counterweight scales play a crucial role in various industrial applications, providing accurate weight measurements essential for operational efficiency. However, the implementation of these scales can come with a set of common challenges. One prevalent issue is the difficulty in achieving precise calibration, especially in environments with fluctuating temperatures and vibrations. According to a report by the International Society of Automation, improper calibration can lead to discrepancies in weight readings by as much as 5%, significantly impacting inventory management and production processes.

Another challenge is the integration of the counterweight scale with existing systems. Many industries are skilled in traditional measurement methods but are hesitant to adapt to new technologies. This reluctance can be tackled through comprehensive training programs, which can enhance staff confidence and proficiency. As highlighted in a survey by the Manufacturing Technology Insights, companies that invest in training for their employees see a 23% boost in the effective implementation of advanced measuring technologies.

**Tips for Successful Implementation:**

- Ensure environmental conditions are stable and conducive for calibration.

- Conduct regular training sessions for staff to familiarize them with the technology.

- Collaborate with technology providers for ongoing support and updates to the scale systems.