In the world of packaging and production, the demand for efficient automation is growing. An Automatic Checkweigher is essential for many industries. It ensures products meet weight specifications accurately. This task may seem simple, but it is highly critical. A small error could lead to significant losses.

As we look ahead to 2026, choosing the best Automatic Checkweigher requires careful consideration. Various models are available, each with distinct features and capabilities. Businesses must evaluate what suits their specific needs best. Some machines offer advanced technology, while others prioritize reliability over innovation.

Understanding the right balance is vital. A model that excels in speed may lack precision. Conversely, a highly precise machine can be slow, impacting production speed. This reality forces us to reflect on what truly matters in our operations. Productivity and accuracy are paramount. The journey to finding the perfect checkweigher may not be straightforward, but the effort is worthwhile.

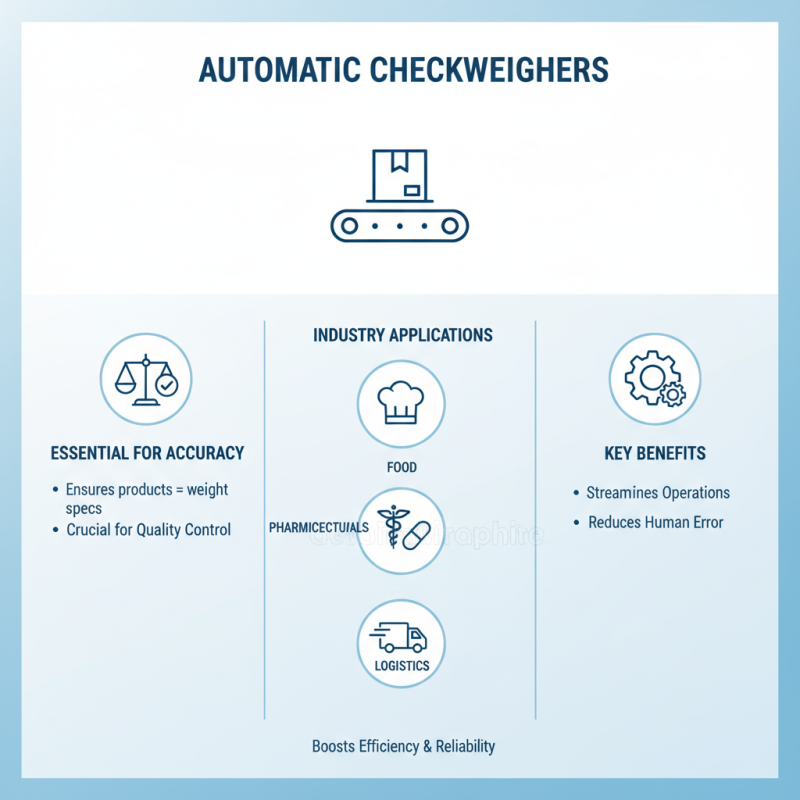

Automatic checkweighers play a crucial role in modern manufacturing and packaging processes. They are devices that automatically measure the weight of products on a production line. The main purpose is to ensure that items meet specified weight criteria. This helps maintain quality control and reduce waste. In high-speed environments, accuracy is vital. Even minor discrepancies can lead to significant financial losses.

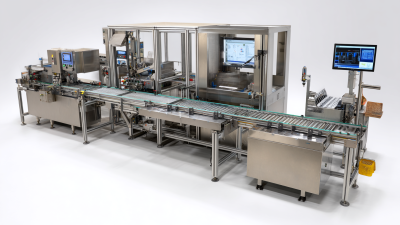

These machines typically feature conveyor systems. They can handle a variety of product shapes and sizes. Whether it's packages or bulk items, the versatility is impressive. However, achieving consistent reliability can be challenging. Calibration is not a one-time task; it requires continuous monitoring. Sometimes, small changes in production can affect weight measurements. It is important to reflect on these variables regularly.

In addition, the technology behind these machines is advancing. Features like intuitive interfaces and data logging are becoming common. Yet, adopting new technology requires training. Many companies struggle with this aspect. They need to balance efficiency with employee readiness. Evaluating the impact of these upgrades is essential for long-term success.

When selecting an automatic checkweigher, several key features stand out. Precision is vital. The checkweigher should deliver accurate weight measurements consistently. Look for models with advanced sensors. These enhance detection and reduce errors. The speed of operation cannot be overlooked. A rapid checkweigher means improved productivity on the production line. However, faster speeds can sometimes compromise accuracy. It's essential to find a balance.

Another important aspect is the flexibility of the checkweigher. It should accommodate various package sizes and weights. Some checkweighers struggle with different products, leading to increased downtime. This can be frustrating in a busy environment. Consider the ease of use too. An intuitive interface can reduce training time. However, not all designs are user-friendly, so this is worth pondering.

Don't forget the maintenance requirements. Some machines need frequent servicing, impacting overall efficiency. Look for options with lower maintenance needs. Lastly, think about the integration capabilities. The automatic checkweigher should seamlessly connect with existing equipment. Compatibility issues can disrupt workflows, causing delays. Balancing these features takes careful thought and consideration.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Weighing Capacity | 0-10 kg | 0-5 kg | 0-15 kg |

| Speed | 100 units/min | 150 units/min | 120 units/min |

| Accuracy | ±0.1 g | ±0.2 g | ±0.05 g |

| Display Type | LCD | LED | Touchscreen |

| Connectivity Options | USB, Ethernet | Wi-Fi, USB | Ethernet, RS232 |

| Dimensions (L x W x H) | 800 x 600 x 550 mm | 700 x 500 x 450 mm | 900 x 700 x 600 mm |

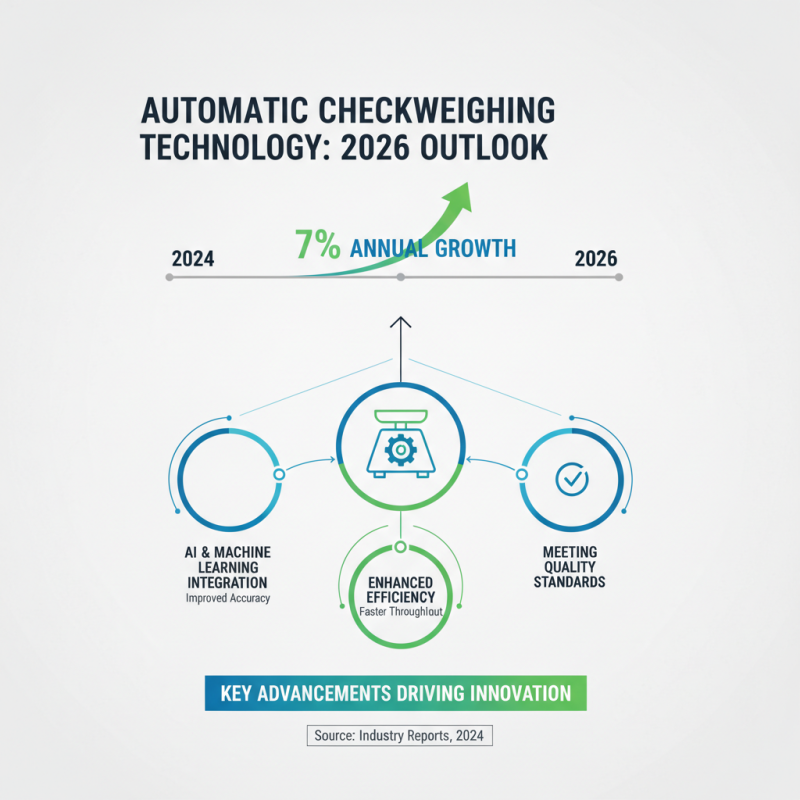

In 2026, the demand for automatic checkweighers is predicted to soar. With advancements in technology, these machines ensure precision and efficiency in various manufacturing sectors. Recent industry reports indicate that the global checkweigher market is expected to grow at a CAGR of 6.5% from 2023 to 2028. This growth accentuates the significance of investing in top-tier checkweighers.

When comparing automatic checkweighers, several key features stand out. Speed and precision are paramount. High-quality machines can reach speeds of up to 200 packs per minute with a margin of error as low as ±0.5 grams. However, maintenance and calibration remain challenges that manufacturers must address. Many models require frequent recalibration, which can lead to downtime. Therefore, ensuring continuous accuracy can be a reflective point for producers.

Moreover, adaptability to different packaging types is essential. Some systems struggle with varied shapes and sizes. Users need versatile solutions that handle diverse products seamlessly. Reports indicate that only 45% of checkweighers in the market today meet multiple product specifications adequately. This gap highlights the necessity for further innovation. Thus, finding an optimal checkweigher involves a careful analysis of these factors.

Automatic checkweighers have become essential in various industries. They ensure that products meet weight specifications. This accuracy is crucial for maintaining quality control. Many manufacturers in food, pharmaceuticals, and logistics benefit significantly from these systems. They streamline operations and reduce human error.

In the food industry, checkweighers help prevent product waste. Overweight products can lead to excess costs. Companies need to balance compliance with budget constraints. However, outdated machines may still create challenges. They can be slow and inefficient, causing bottlenecks in production lines. This requires businesses to assess their current equipment. Some might hesitate to invest in newer technology due to initial costs.

Pharmaceutical companies rely on precise measurements. Automatic checkweighers help maintain stringent quality standards. A small error can have serious consequences. However, implementing these systems isn't without its hurdles. Training staff on new machines can be daunting. Companies must be willing to adapt and learn. It’s a constant cycle of improvement and reflection.

As we look toward 2026, automatic checkweighing technology is poised for transformative advancements. Industry reports indicate that the automatic checkweighing market is expected to grow by 7% annually. The integration of AI and machine learning will improve accuracy and efficiency. These technologies will help manufacturers meet rising quality standards.

Another emerging trend is the adoption of smart sensors. These sensors can monitor weight in real-time, providing immediate feedback. They enhance productivity by reducing waste and ensuring compliance with regulations. Explicitly designed interfaces will simplify operations, making it easier for personnel to navigate complex systems.

Remember, when choosing checkweighers, consider your specific needs. Efficiency is crucial, but don’t overlook support and maintenance. Investing in training for your team is equally vital. Evaluate your current processes critically. Are you maximizing the potential of your equipment? Continuous improvement is essential in this fast-evolving sector.