In today's fast-paced manufacturing environment, efficiency and accuracy are critical. Dynamic checkweighers have emerged as essential tools for production lines. According to a 2022 industry report by Statista, around 75% of manufacturers implemented dynamic checkweighing systems to enhance quality control. These advanced machines not only streamline operations but also minimize product waste.

John Smith, an industry expert and a senior engineer at TechSolutions, emphasizes, "Dynamic checkweighers significantly reduce inaccuracies and improve overall productivity." However, with the ever-evolving technology, it's essential to continuously assess and refine these systems. Many companies face challenges integrating dynamic checkweighers into existing workflows. Production lines can struggle with compatibility, leading to delays and inefficiencies.

Moreover, understanding the full capabilities of a dynamic checkweigher is often overlooked. Proper training and awareness are crucial for maximizing their potential. Addressing these shortcomings can lead to improved results. In an industry focused on quality, it's vital to constantly seek the best solutions. Quality control should never be an afterthought. Implementing dynamic checkweighers is a step in the right direction, but recognizing their limitations is equally important.

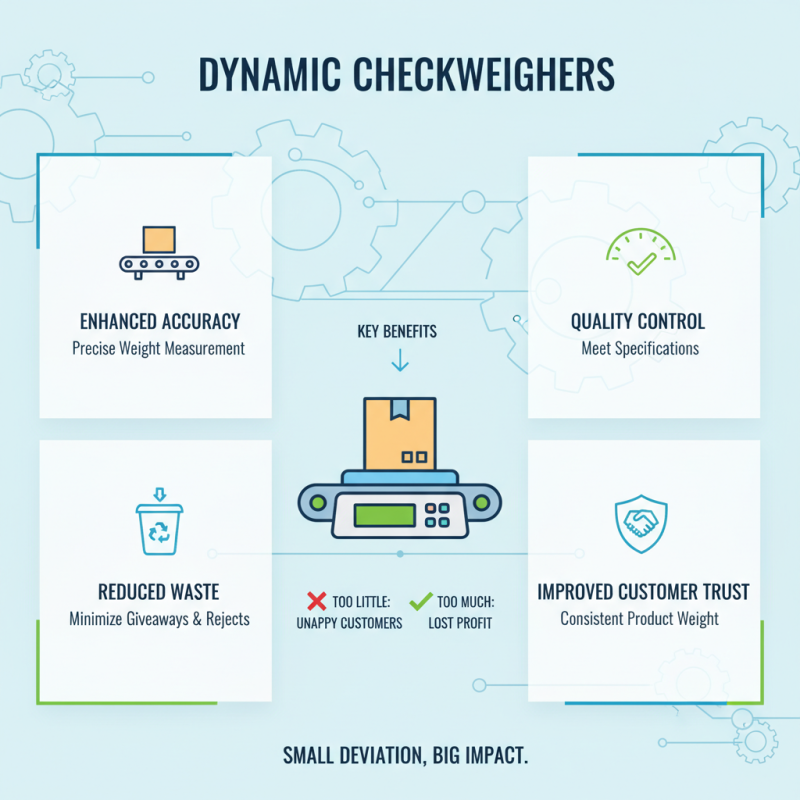

Dynamic checkweighers play a crucial role in modern production lines by enhancing accuracy in weight measurement. They ensure that products meet specified weight requirements, reducing waste and improving quality control. A small deviation in weight can lead to significant issues. Too much product leads to unnecessary expenses, while too little can damage customer trust.

Improving weight accuracy affects the bottom line. Dynamic checkweighers catch errors in real-time, allowing for immediate corrections. This prevents mispacked items from reaching consumers. An accurate measurement system also enhances compliance with industry regulations. Even minor inconsistencies can trigger audits or recalls, making accuracy essential.

Tips: Maintain your checkweigher regularly. Regular maintenance ensures optimal performance. Staff should be trained to spot anomalies quickly. Monitor weight variations to identify trends in data. This proactive approach can lead to process improvements over time. Understanding limitations in technology is also important. Not every situation is ideal, and some adjustments may be necessary to achieve desired outcomes.

Dynamic checkweighers play a crucial role in modern production lines. They ensure the accuracy of product weights, which improves overall efficiency. Automated processes can significantly reduce human error. This leads to fewer product recalls and waste.

Tips: Regularly calibrate checkweighers. This keeps measurements consistent and reliable. Also, train staff on how to manage the machines. Effective operation requires understanding both the technology and workflow.

Automated checkweighing allows for real-time data collection. This data provides insights into production trends. Companies can identify issues quickly and adjust processes. However, implementing automation can initially be costly. Businesses must weigh the costs against long-term benefits.

Tips: Start small with automation. Assess how it fits into your current system. Take gradual steps to fully integrate new technology. Balance between innovation and practicality is vital.

This bar chart illustrates the key benefits of using dynamic checkweighers in production lines, focusing on improved production efficiency through automated processes. The data represents various efficiency metrics achieved by implementing dynamic checkweighers.

Dynamic checkweighers play a crucial role in modern production lines. They help reduce product waste significantly. By precisely measuring the weight of items as they move along the line, these machines ensure consistency. This accuracy prevents underfilling or overfilling, which can lead to discarded products.

Cost savings are another major benefit. Fewer wasted items lead directly to increased profit margins. With dynamic checkweighers in place, manufacturers can also optimize their ingredient usage. This allows for better inventory management. The financial gains can be quite substantial over time, even with initial investments in technology.

However, the integration of dynamic checkweighers is not without its challenges. Training staff to operate equipment effectively can be time-consuming. There may be occasional calibration issues that need addressing. Inspecting machinery regularly can feel tedious but is essential for maintaining accuracy. These reflections highlight the importance of adapting processes for continuous improvement.

In modern production lines, compliance with regulatory standards is essential. Dynamic checkweighers play a critical role in achieving this. According to industry reports, over 75% of food manufacturers are facing growing scrutiny over weight and labeling accuracy. Checkweighers help ensure that products meet legal requirements while minimizing waste.

Monitoring weight in real-time can reduce the risk of product recalls. Recalls not only damage brand reputation but can cost companies millions. A report from a manufacturing association notes that improper weight can lead to fines of up to $100,000. Thus, implementing a dynamic checkweigher can safeguard against such costly errors.

Tips: Regularly calibrate checkweighers for accuracy. Ensure your staff is trained properly to interpret data effectively. Invest in technology that can adapt to changing regulations. This will help maintain compliance and improve product quality. Remember, even minor inaccuracies can lead to major compliance issues in the long run.

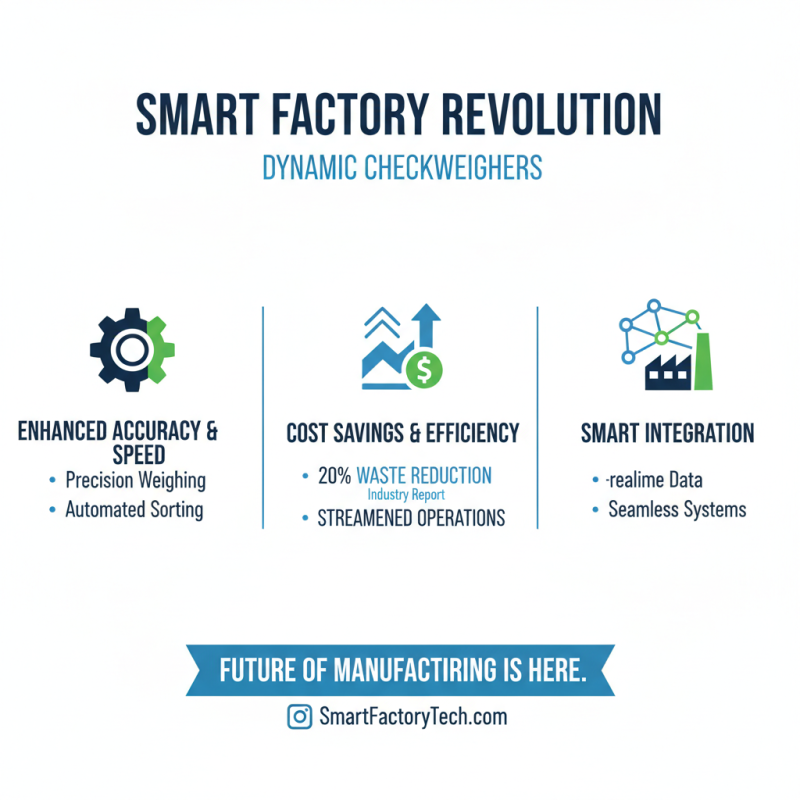

The integration of dynamic checkweighers into smart factory systems is revolutionizing production lines. These advanced devices not only enhance accuracy but also streamline operations. A recent industry report highlighted that manufacturers can reduce waste by up to 20% with dynamic checkweighers. This efficiency also leads to cost savings.

Dynamic checkweighers can automate the weighing process, providing real-time data that aids in quality control. However, it is crucial to consider the training of staff. Operators must be familiar with both the technology and quality standards. Without proper understanding, the benefits of the system may not be fully realized.

While many companies rush to adopt cutting-edge technology, not all achieve the desired outcome. A survey indicated that 30% of organizations struggle with integration issues. Addressing these challenges requires careful planning and ongoing evaluation. Integrating dynamic checkweighers is a significant step, but it demands reflection on workforce readiness and system compatibility.