In the ever-evolving landscape of manufacturing and production, ensuring precise measurement is paramount. The integration of technology has brought forth innovative solutions, among which the Checkweighing Machine stands out as a vital tool for achieving accuracy in weighing and maintaining quality control. These machines are designed to provide precise weight measurements, helping manufacturers comply with regulatory standards and meet consumer expectations for product quality.

Utilizing a Checkweighing Machine not only enhances operational efficiency but also minimizes waste by ensuring that products meet specified weight requirements before reaching the market. This proactive approach to quality control allows companies to identify discrepancies in weight, thereby reducing the risk of overfilling or underfilling products. By implementing such technology, businesses can bolster their reputation for reliability while simultaneously optimizing their production processes.

As industries continue to prioritize accuracy and quality in their operations, the Checkweighing Machine proves to be an indispensable asset. Its role is not merely limited to weight measurement; it serves as a cornerstone for achieving overall quality assurance, fostering trust between manufacturers and consumers alike. In the following sections, we will explore the top benefits associated with the use of Checkweighing Machines, illustrating their crucial impact on modern manufacturing practices.

Checkweighing machines play a crucial role in industries where precision is paramount. These machines are designed to ensure that products meet specific weight criteria, which is vital for maintaining quality standards. One of the key features of checkweighing machines is their ability to perform high-speed weighing while maintaining accuracy. This speed ensures efficiency in production lines, minimizing delays and maximizing output without compromising quality.

Another important aspect is the integration of advanced technology such as dynamical weighing and statistical process control. This helps operators quickly identify any discrepancies in product weight, allowing for immediate adjustments to prevent waste and ensure compliance with regulations. Furthermore, many modern machines come equipped with intuitive user interfaces, making it easier for operators to monitor weight variances and make informed decisions quickly.

Tips: When selecting a checkweighing machine, consider factors such as the required weight range, speed of operation, and ease of calibration. Regular maintenance is also crucial to ensure the machine's lasting accuracy. Investing in a machine that allows for software updates can provide long-term benefits by adapting to the evolving needs of your production process.

Checkweighing machines play a crucial role in quality control processes across various industries, ensuring that products meet specified weight standards. These machines are designed to automatically verify the weight of items during the production line, thus helping to maintain compliance with regulatory requirements and customer expectations. By identifying any deviations from required weights, checkweighing systems help manufacturers reduce waste, minimize errors, and enhance overall product quality. The integration of checkweighers into production lines allows for immediate feedback, which can trigger necessary adjustments to machinery settings, thereby promoting consistency and reliability in product output.

Furthermore, the data captured by checkweighing machines can be analyzed to identify trends and patterns over time, providing valuable insights into production efficiency. This data-driven approach not only aids in detecting anomalies in weight that might indicate issues with the production process but also supports continuous improvement initiatives. Companies utilizing checkweighing machines are often able to enhance their quality control protocols, ensuring that they produce items that not only meet their weight specifications but also align with the highest standards of quality and safety. Ultimately, checkweighers reinforce a commitment to quality by integrating precision weighing directly into the manufacturing workflow.

Automated checkweighing systems offer numerous advantages over traditional manual methods, especially in industries where precision and efficiency are paramount. One of the primary benefits of automation is the significant reduction in human error. Automated systems utilize advanced technology to ensure that each item is weighed consistently and accurately, minimizing discrepancies that can arise from manual handling. This level of precision is crucial for maintaining quality control, as even slight variations can affect the overall integrity of products.

Another noteworthy advantage of automated checkweighing is the enhanced speed and productivity it brings to processing. Unlike manual weighing, which can be time-consuming and labor-intensive, automated systems operate continuously and can handle a higher throughput. This ensures that production lines run smoothly without the interruptions that can occur when relying on manual checks. Furthermore, automated systems can be integrated with other production processes, allowing for real-time data collection and analysis. This capability not only streamlines operations but also provides valuable insights into product quality and consistency, enabling companies to make informed adjustments and maintain high standards in their output.

Checkweighing machines play a critical role in various industries by ensuring that products meet specific weight standards. In the food and beverage sector, these machines are essential for compliance with regulations and maintaining quality control. They help manufacturers prevent underfilling or overfilling of products, which directly affects customer satisfaction and operational efficiency. From packaging ready-to-eat meals to bottled beverages, checkweighers ensure that each item meets the required weight, thus minimizing wastage and reducing costs associated with product recalls.

In the pharmaceutical industry, checkweighing machines are utilized to ensure that medication doses are accurate and consistent. This accuracy is vital not only for compliance with health regulations but also for patient safety. The machines can handle various formats, from tablets to liquid formulations, effectively managing the diverse weighing needs of pharmaceuticals. Moreover, checkweighing technologies are increasingly being integrated into automated production lines, enhancing overall productivity and reliability across sectors, including cosmetics and chemicals, where precise measurements are essential for quality assurance and operational effectiveness.

| Industry | Common Applications | Benefits | Accuracy (% of Specified Weight) | Cost Savings |

|---|---|---|---|---|

| Food & Beverage | Portion Control, Packaging | Reduced Waste, Consistency | ±0.1% | Up to 20% Reduction |

| Pharmaceutical | Drug Dosage, Quality Control | Compliance, Safety | ±0.05% | Up to 15% Reduction |

| Chemical | Batching, Formulation | Precision, Regulatory Compliance | ±0.2% | Up to 10% Reduction |

| Textiles | Material Weighing, Production Control | Quality Assurance, Inventory Management | ±0.3% | Up to 18% Reduction |

| Logistics | Freight Weighing, Cargo Inspection | Cost Efficiency, Compliance with Regulations | ±0.5% | Up to 25% Reduction |

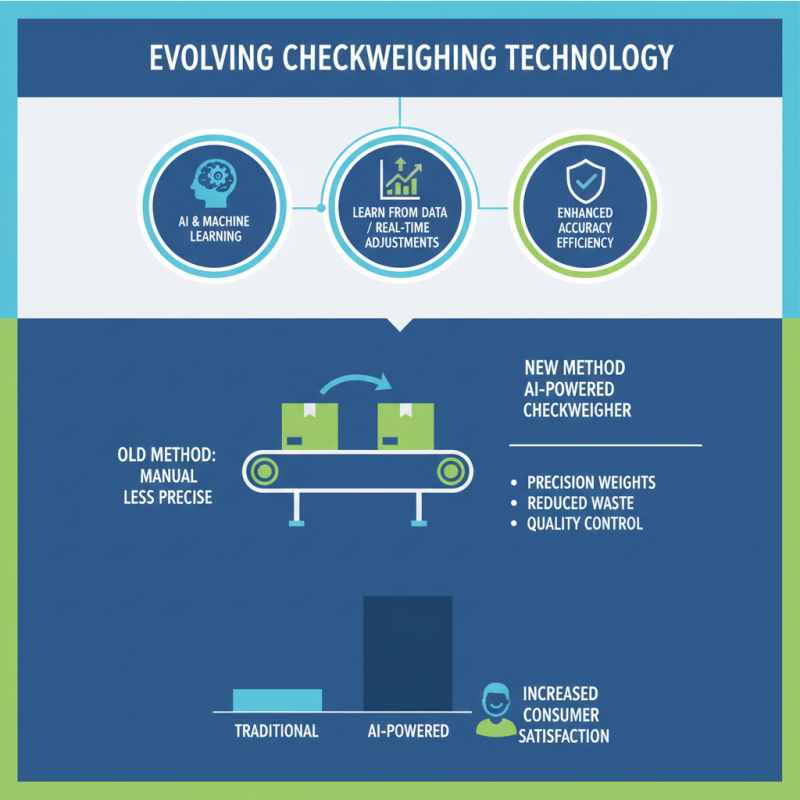

The landscape of checkweighing technology is evolving rapidly, with a focus on enhancing accuracy and efficiency in various industries. One of the most exciting trends is the integration of artificial intelligence (AI) and machine learning algorithms into checkweighing machines. These advanced technologies enable systems to learn from past data, improving their decision-making capabilities by adjusting weighing processes in real time. As a result, manufacturers can achieve unprecedented levels of precision in weight measurement and product quality, reducing waste and increasing consumer satisfaction.

Another significant trend is the adoption of IoT (Internet of Things) connectivity in checkweighing systems. By connecting devices to the cloud, operators can access real-time weight data and analytics from anywhere, allowing for better monitoring and informed decision-making. This interconnected approach not only enhances accuracy but also streamlines operations, as businesses can quickly identify and rectify discrepancies or issues in their production lines.

**Tips:** To optimize your checkweighing process, ensure regular calibration of your machines to maintain accuracy. Implementing a routine maintenance schedule can also help catch potential issues before they affect production. Additionally, training staff on the importance of accurate weighing can promote a culture of quality control, further enhancing the overall effectiveness of your operations.