In today's competitive manufacturing landscape, the ability to enhance process efficiency is paramount. One of the most effective tools available for manufacturers is the Automatic Checkweigher. According to industry expert Dr. Emily Hartman, a renowned specialist in packaging technology, "Implementing an Automatic Checkweigher can drastically minimize production errors and optimize resource allocation." This underscores the critical role that accurate weight measurement plays in ensuring quality control and streamlining manufacturing operations.

The Automatic Checkweigher not only ensures compliance with regulatory standards but also helps reduce waste by ensuring that each product meets the specified weight criteria. This technology allows manufacturers to achieve greater accuracy and consistency in their processes, leading to improved overall efficiency. As manufacturers seek to refine their operations and reduce costs, the adoption of Automatic Checkweighers becomes an essential strategy.

By leveraging the capabilities of an Automatic Checkweigher, businesses can enhance their productivity, maintain high-quality outputs, and ultimately gain a competitive edge in the market. As Dr. Hartman aptly states, "Investing in automation is no longer an option; it's a necessity for those aiming to thrive in the modern manufacturing environment.

Automatic checkweighers have emerged as vital components in modern manufacturing processes, especially in industries such as food and beverage, pharmaceuticals, and consumer goods. These devices ensure that products meet weight specifications, thereby reducing waste, optimizing production efficiency, and enhancing quality control. According to a recent report from the Association for Packaging and Processing Technologies, companies that implement automatic checkweighers can see a productivity increase of up to 15% while significantly minimizing product giveaway.

One significant advantage of using automatic checkweighers lies in their ability to maintain consistent quality standards. A study by the Food and Drug Administration highlighted that industries utilizing automated weighing systems report fewer instances of non-compliance regarding product weights, which in turn lowers the risk of costly fines and recalls. Furthermore, integrating checkweighers into production lines enables real-time data collection, allowing for immediate adjustments in the manufacturing process and ensuring that every product meets the desired specifications.

**Tip:** Regular calibration of your checkweigher can ensure optimal accuracy and compliance with industry standards. This routine maintenance prevents deviations that could lead to expensive product losses or regulatory issues.

In addition to improving accuracy, these systems help manufacturers identify trends over time. By analyzing the weight data collected by checkweighers, businesses can uncover inefficiencies in their processes, adapt to changing market demands, and ultimately enhance their competitive edge.

**Tip:** Consider investing in advanced analytics tools that work in conjunction with checkweighers to identify patterns and forecast trends, helping you stay ahead in a competitive marketplace.

| Dimension | Importance | Impact on Efficiency |

|---|---|---|

| Throughput Rate | High throughput ensures operational efficiency and faster production times. | Increased throughput can lead to reduced costs and higher revenue. |

| Accuracy | Minimizing errors is crucial for product quality and customer satisfaction. | Improved accuracy reduces waste and returns, enhancing profitability. |

| Compliance | Meeting industry standards and regulations is essential for market access. | Ensures smooth operations and avoids potential fines or shutdowns. |

| Integration | Easy integration with existing systems enhances workflow. | Seamless operations boost overall manufacturing agility. |

| Maintenance | Accessibility for maintenance ensures longevity and reliability. | Regular maintenance reduces downtime, increasing production stability. |

In manufacturing, accuracy plays a pivotal role in optimizing efficiency and reducing costs. An automatic checkweigher ensures that products meet weight specifications, minimizing the likelihood of overfilling or underfilling. This precision not only prevents waste but also helps maintain compliance with regulations, which can otherwise result in fines or recalls. By integrating an automatic checkweigher into the production line, manufacturers can enhance productivity through real-time monitoring and adjustments, leading to significant operational improvements.

**Tip:** Regularly calibrate your checkweigher to ensure peak accuracy. Small deviations can lead to large discrepancies over time, impacting not just product quality but also financial performance.

Moreover, the increased accuracy facilitated by automatic checkweighers contributes to better resource management. When products are consistently within the desired weight range, manufacturers can optimize their material usage, thereby reducing costs associated with excess raw materials. This efficiency creates a ripple effect, enhancing the overall quality of the final product and improving customer satisfaction.

**Tip:** Analyze the data collected from checkweighers to identify trends in weight fluctuations, allowing for proactive adjustments in your manufacturing process. This can lead to further efficiencies and cost savings.

Implementing automatic checkweighers in manufacturing processes offers several advantages over traditional manual methods, significantly enhancing overall efficiency. According to a report by the Food and Beverage Manufacturers Federation, 65% of companies that transitioned to automatic checkweighers noted a marked increase in production speed, as these systems can process hundreds of items per minute with minimal human intervention. This not only accelerates the packaging and shipping phases but also minimizes bottlenecks often caused by manual checking.

Moreover, automatic checkweighers contribute to improved accuracy in weight measurement, which is crucial for compliance with industry standards and regulations. A study conducted by the Institute of Packaging Professionals indicated that businesses employing automatic weight checking systems achieved a 30% reduction in product giveaways due to more precise weight management. This leads to significant cost savings and optimizes resource utilization, allowing manufacturers to better manage their operational budgets. By reducing human error associated with manual weighing, manufacturers can also enhance their reputation for quality and reliability in their products.

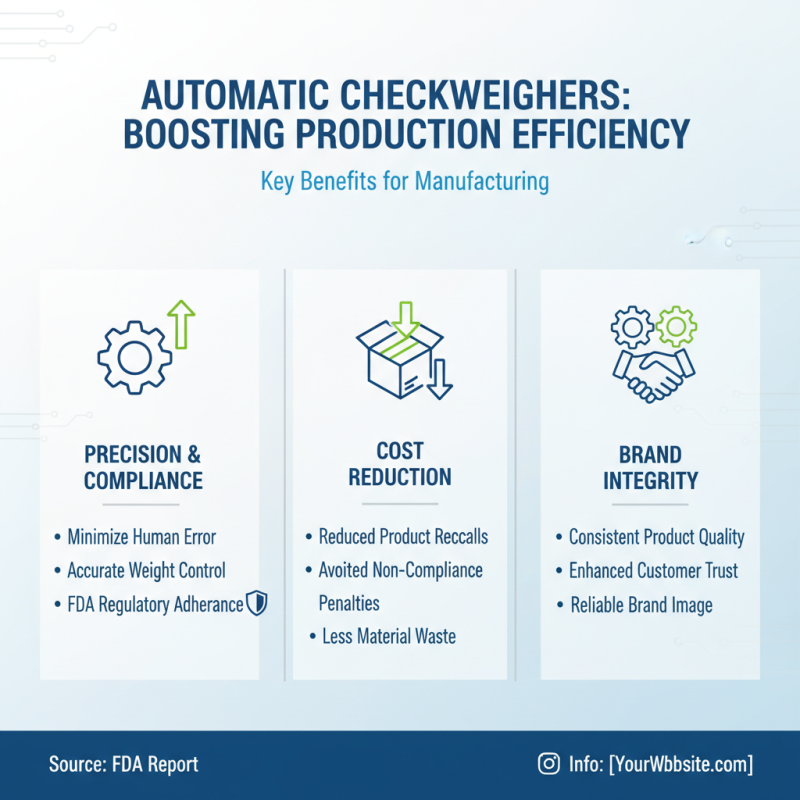

The integration of automatic checkweighers into production lines is increasingly becoming a crucial factor in enhancing operational efficiency across various manufacturing sectors. A report by the Food and Drug Administration (FDA) highlights that accurate weight measurements are essential to comply with regulatory standards and ensure product quality. By incorporating automatic checkweighers, manufacturers can minimize the risk of human error and achieve precise weight control, which can lead to significant reductions in product recalls and non-compliance penalties, ultimately retaining customer trust and brand integrity.

Moreover, according to a study published by the Association for Packaging and Processing Technologies, the implementation of automatic checkweighing systems can enhance production throughput by up to 20%. This impressive increase can be attributed to the real-time feedback provided by the equipment, which allows for immediate adjustments to the fill process. Additionally, automatic checkweighers can streamline workflow as they can be seamlessly integrated into existing production lines, reducing labor costs while promoting operational consistency. This automation not only enhances efficiency but also enables manufacturers to allocate their human resources to more critical tasks that require cognitive skills, thus improving overall productivity.

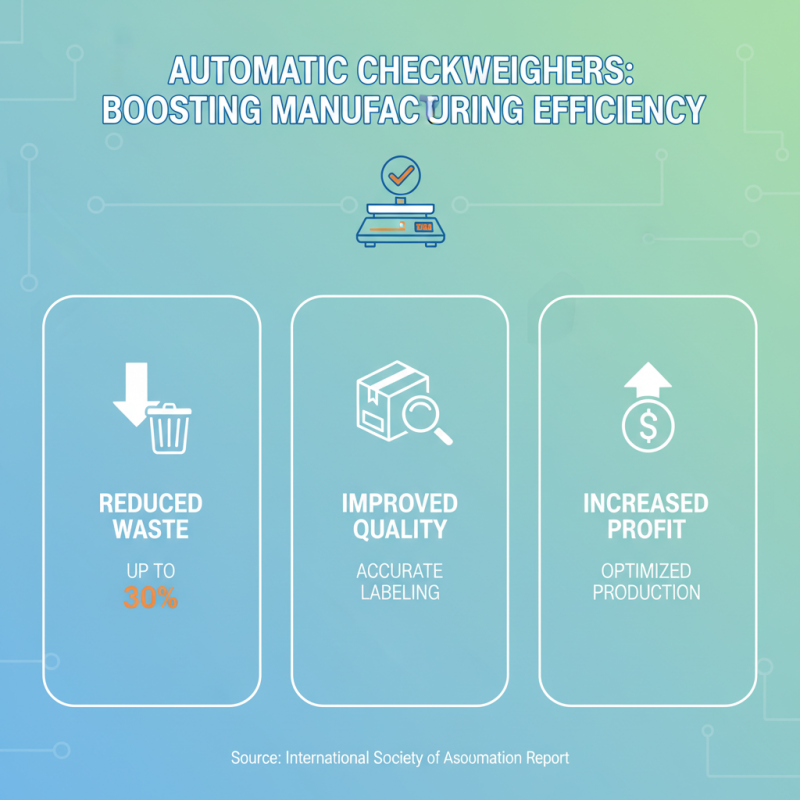

In today's competitive manufacturing landscape, utilizing an automatic checkweigher is paramount for ensuring process efficiency and maintaining product quality. Choosing the right checkweigher involves understanding the specific needs of your operation and the type of products you handle. According to a report by the International Society of Automation, manufacturers that implement automated quality control systems, such as checkweighers, experience a reduction of up to 30% in product waste and mislabeling, significantly boosting their bottom line.

When selecting a checkweigher, consider factors such as accuracy, speed, and integration capabilities with existing production lines. It's crucial to choose equipment that not only meets your current operational demands but also has the flexibility to adapt to future changes. Regular maintenance is another critical aspect, as neglect can lead to inaccurate readings and operational downtime. The Food and Drug Administration (FDA) recommends establishing a rigorous maintenance schedule to ensure the longevity and precision of checkweighers, which can enhance compliance with industry regulations and improve overall product safety.

**Tips:**

- Make sure to conduct a thorough assessment of your production environment and product characteristics to determine the most suitable checkweigher specifications.

- Develop a comprehensive maintenance plan that includes routine calibration and servicing to ensure optimal performance and compliance.

- Educate your team on best practices for using checkweighers, as operator training can significantly impact accuracy and effectiveness in the long run.